fitz_calc

- 41

- 0

A mechanical design question, just wanted to pick your brains about a project I'm working on.

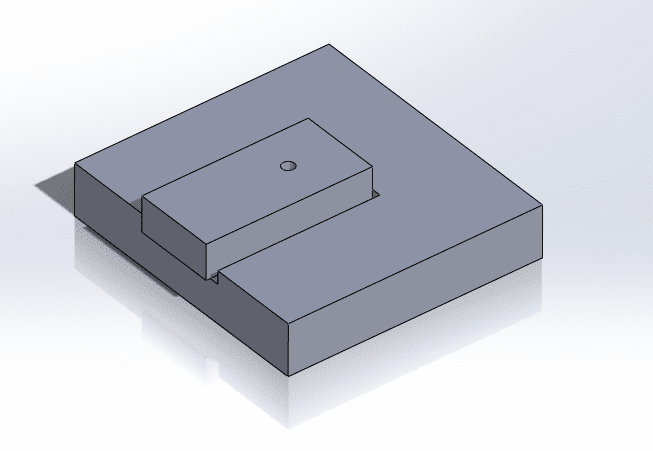

I have a fixture that houses a magnet, when an operator loads a part with a screw the magnet jumps and a thru beam on the magnet detects that a screw is present. Without a screw (below) the magnet stays home and the process fails.

I have a new part, the screw location is 15mm from the current screw location. My magnet will only accommodate 10mm range so I need to come up with something else. One idea I had was to slot my fixture, install reflective tape, and place a retro reflective sensor near the back of the fixture; if a screw is absent the sensor will detect light.

My concern with this design is an operator could potentially block the sensor and get a false pass. I'm running out of ideas, what are your thoughts?

I have a fixture that houses a magnet, when an operator loads a part with a screw the magnet jumps and a thru beam on the magnet detects that a screw is present. Without a screw (below) the magnet stays home and the process fails.

I have a new part, the screw location is 15mm from the current screw location. My magnet will only accommodate 10mm range so I need to come up with something else. One idea I had was to slot my fixture, install reflective tape, and place a retro reflective sensor near the back of the fixture; if a screw is absent the sensor will detect light.

My concern with this design is an operator could potentially block the sensor and get a false pass. I'm running out of ideas, what are your thoughts?