Discussion Overview

The discussion centers on the functionality of centrifugal clutches, specifically whether they operate effectively in both rotational directions. Participants explore the mechanics of centrifugal clutches, including the role of wedging action and centrifugal force in generating friction against the drum.

Discussion Character

- Technical explanation

- Debate/contested

Main Points Raised

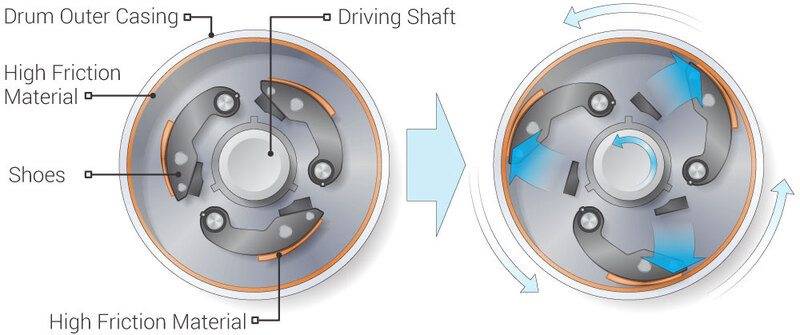

- One participant describes how the wedging action of the shoe arm in a centrifugal clutch increases friction against the drum, suggesting that this action may not occur when the clutch rotates in the reverse direction.

- Another participant notes that the specific centrifugal clutch in question is designed to transmit torque in one direction, raising the question of how much friction is attributable to centrifugal force versus wedging action, depending on the pivot locations relative to the drum.

- A different viewpoint asserts that centrifugal clutches can work in both directions, but they may transfer more torque in one direction due to the friction dynamics between the cams and the drum, which can lead to rapid locking in one direction while slipping in the other.

- One participant introduces the concepts of "self-energizing" and "self-locking," relating these principles to drum brakes and suggesting that similar mechanisms could apply to centrifugal clutches.

Areas of Agreement / Disagreement

Participants express differing views on the effectiveness of centrifugal clutches in reverse. While some assert that they can work in both directions, others emphasize that performance may vary significantly based on design and operational conditions.

Contextual Notes

The discussion highlights the dependence on specific design features, such as cam angles and pivot locations, which influence the clutch's behavior in different rotational directions. There are unresolved questions regarding the exact contributions of centrifugal force and wedging action to overall friction.