arehman1289

- 11

- 0

Hello Everybody,

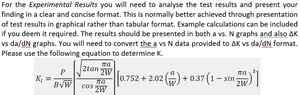

Im doing my lab report on Fatigue testing for a Single Edge Notched Tension (SENT) sample and need to plot ΔK vs da/dN for a series of a vs N readings at different R and maximum stress values (attached in the picture). I've just been given one equation for Ki and told that I need to use ASTM E647 for assistance (attached equation). However after hours of going through it I was unable to figure out how to get ΔK vs da/dN from the data and information. Any step by step help would be highly appreciated. Please please.

Thanks

Im doing my lab report on Fatigue testing for a Single Edge Notched Tension (SENT) sample and need to plot ΔK vs da/dN for a series of a vs N readings at different R and maximum stress values (attached in the picture). I've just been given one equation for Ki and told that I need to use ASTM E647 for assistance (attached equation). However after hours of going through it I was unable to figure out how to get ΔK vs da/dN from the data and information. Any step by step help would be highly appreciated. Please please.

Thanks