Discussion Overview

The discussion centers around calculating the torque required for a linear telescopic cable mechanism being designed for a school project. Participants explore various aspects of the design, including cable routing, bearing friction, and mechanical configurations that may affect the torque calculations.

Discussion Character

- Exploratory

- Technical explanation

- Debate/contested

- Homework-related

Main Points Raised

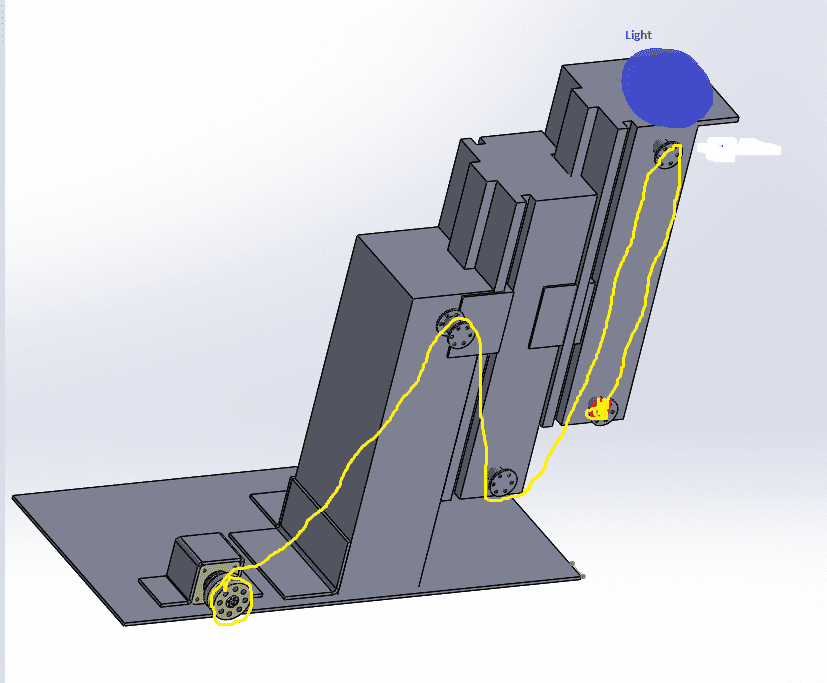

- One participant seeks guidance on calculating the required torque for a telescopic system elevated by a step motor, noting the complexity added by a moving pulley.

- Another participant raises concerns about the horizontal offset of the stages, suggesting it may introduce extra stress and friction, and questions the cable routing between stages.

- Some participants discuss the importance of keeping the vertical mechanism co-axial to minimize bending stress and friction, referencing a video for design insights.

- There are suggestions to redesign the mechanism to be more coaxial to reduce friction and torque requirements, with one participant emphasizing the need to address design issues before calculating torque.

- One participant mentions that friction resistance may vary with height due to changing normal forces as the load is elevated, complicating torque calculations.

- Another participant notes modifications made to the design to reduce bearing friction, including increasing pulley diameters and adding additional pulleys, while seeking further evaluation of these changes.

- Some participants express differing views on whether the modifications effectively reduce friction, with suggestions for tilting the mechanism to better align loads over the center of mass.

- Links to external resources are provided for studying real-life telescopic lifts and their power requirements, highlighting design features that reduce friction.

Areas of Agreement / Disagreement

Participants generally agree on the importance of minimizing friction and optimizing design for torque calculations, but there are multiple competing views regarding the effectiveness of proposed modifications and the best design approach. The discussion remains unresolved on several technical points.

Contextual Notes

Participants express uncertainty about the impact of design choices on torque requirements, including the effects of cable routing, bearing friction, and mechanical configurations. There are also unresolved mathematical considerations related to torque calculations based on the described designs.