rodoka

- 2

- 0

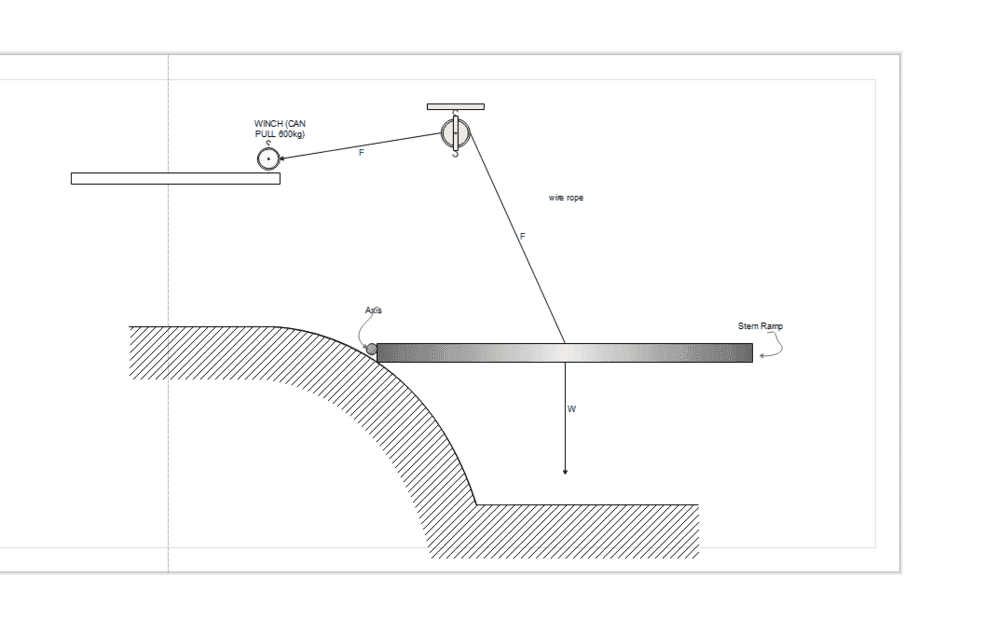

Hi i got a problem and i want to share it with you guys. i am new in the forum. Today i was in a shipyard trying to fix a ship's ramp.

The sketch shows that the wire rope is connected to the middle of the ramp. But i think that it is better to connect it to the edge of the ramp because the winch will work more restful. But in the other hand if i put it on the edge, the winch will not bring the ramp up instead of pulling it. what's your opinion? what if the Block-pulley should be placed little bit right? The ramp is about 250kg weight Sorry for bad the english its not my native language

The sketch shows that the wire rope is connected to the middle of the ramp. But i think that it is better to connect it to the edge of the ramp because the winch will work more restful. But in the other hand if i put it on the edge, the winch will not bring the ramp up instead of pulling it. what's your opinion? what if the Block-pulley should be placed little bit right? The ramp is about 250kg weight Sorry for bad the english its not my native language