krissturm

- 1

- 1

Hello,

Looking for help with a physics problem.

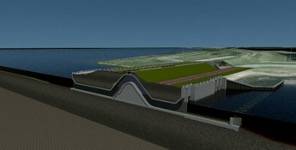

I am dealing with a problem regarding the flow discharge between 2 open water bodies connected by a concrete sluice with gates. The issue is that the channel is not straight but rather a trapezoid (image of the cross-section below). The discharge from 1 of the gates is said to be ~50m^3/s and the average velocity is between 3-5 m/s.

I would like to know what kind of formulas should I be looking for when dealing with such a shape. In the middle of the dike, there is a vacuum suction divide that creates a vacuum so that the water can flow freely. Additionally, a vertical axis turbine will be installed there so how should I approach the losses that the turbine will add to the flow rate?

The length from 1 basin to the other is 65m. The openings are 3.2m x 3.2m and the water level on one side is approx. -80cm NAP and on the other side approx. -30cm NAP

Looking for help with a physics problem.

I am dealing with a problem regarding the flow discharge between 2 open water bodies connected by a concrete sluice with gates. The issue is that the channel is not straight but rather a trapezoid (image of the cross-section below). The discharge from 1 of the gates is said to be ~50m^3/s and the average velocity is between 3-5 m/s.

I would like to know what kind of formulas should I be looking for when dealing with such a shape. In the middle of the dike, there is a vacuum suction divide that creates a vacuum so that the water can flow freely. Additionally, a vertical axis turbine will be installed there so how should I approach the losses that the turbine will add to the flow rate?

The length from 1 basin to the other is 65m. The openings are 3.2m x 3.2m and the water level on one side is approx. -80cm NAP and on the other side approx. -30cm NAP

Last edited by a moderator: