chapuis60

- 6

- 1

Hi all

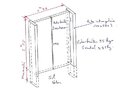

In order to make a metal preframe for a French window as an entrance door, I began to estimate the possibility of building it in rectangular steel tubes of 100 x 50 x 3 mm, laid independently of the walls that could not accept such a load because it was timber framed. The preframe will consist of 2 uprights of 2m80 including 50 cm embedded in a concrete slab and a horizontal beam of 1m30 in the high position. The 2-leaf PVC patio door weighs about 90 kilos.

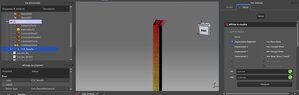

I started to simulate the resistance of the uprights without the horizontal beam under Freecad by imposing a horizontal force of 150 kg, I find a boom of about 19 mm. Could someone confirm this value?

Wouldn't a 100 x 50 UPN or other profile (uneven angle) do the trick?

Thank you.

In order to make a metal preframe for a French window as an entrance door, I began to estimate the possibility of building it in rectangular steel tubes of 100 x 50 x 3 mm, laid independently of the walls that could not accept such a load because it was timber framed. The preframe will consist of 2 uprights of 2m80 including 50 cm embedded in a concrete slab and a horizontal beam of 1m30 in the high position. The 2-leaf PVC patio door weighs about 90 kilos.

I started to simulate the resistance of the uprights without the horizontal beam under Freecad by imposing a horizontal force of 150 kg, I find a boom of about 19 mm. Could someone confirm this value?

Wouldn't a 100 x 50 UPN or other profile (uneven angle) do the trick?

Thank you.