- #1

akong83

- 1

- 0

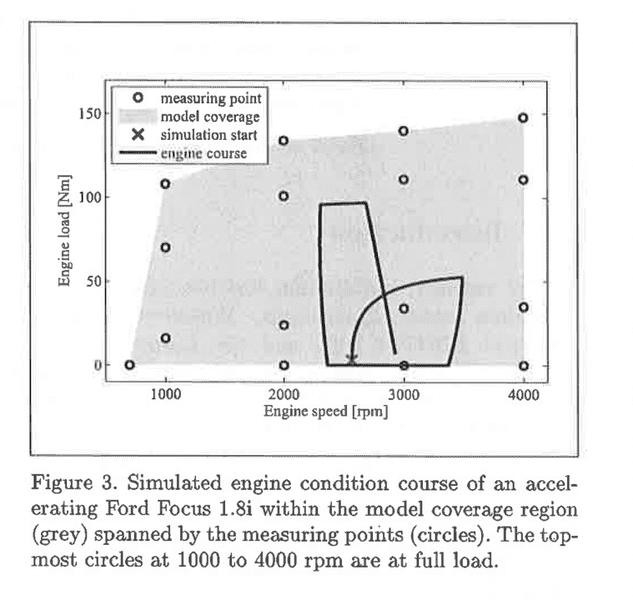

Ive been struggling with this for days trying to make sense of a rpm vs torque chart I've seen recently.

The chart states the engine load was measured 100% 70% 40% 0% and at 1000 2000 3000 4000 rpm. How is this done if using a chasis dyno?

I attached the chart for reference.

That's my question, but below i'll ellaborate on my thinking and hopefully there will be a clear error in my understanding...

I think part of my problem is that I am unsure what the throttle is doing when these charts are produced using the dyno.

Am I right in thinking that to get the 100% load points over each rpm, the test is started with the engine idling then pushing the throttle to 100%. The RPM will increase rapidly upto redline and the engine torque at each RPM can be estimated working back from wheel RPM and transmission ratio etc. They measure at 4 discrete RPM though, suggesting they might have control over the dyno resitive force?

The chart states the engine load was measured 100% 70% 40% 0% and at 1000 2000 3000 4000 rpm. How is this done if using a chasis dyno?

I attached the chart for reference.

That's my question, but below i'll ellaborate on my thinking and hopefully there will be a clear error in my understanding...

I think part of my problem is that I am unsure what the throttle is doing when these charts are produced using the dyno.

Am I right in thinking that to get the 100% load points over each rpm, the test is started with the engine idling then pushing the throttle to 100%. The RPM will increase rapidly upto redline and the engine torque at each RPM can be estimated working back from wheel RPM and transmission ratio etc. They measure at 4 discrete RPM though, suggesting they might have control over the dyno resitive force?