Discussion Overview

The discussion revolves around the challenge of uncoupling the slide mechanism of an office chair, with participants sharing various methods and tools to achieve this. The scope includes practical problem-solving and potential techniques for disassembly.

Discussion Character

- Exploratory

- Technical explanation

- Debate/contested

Main Points Raised

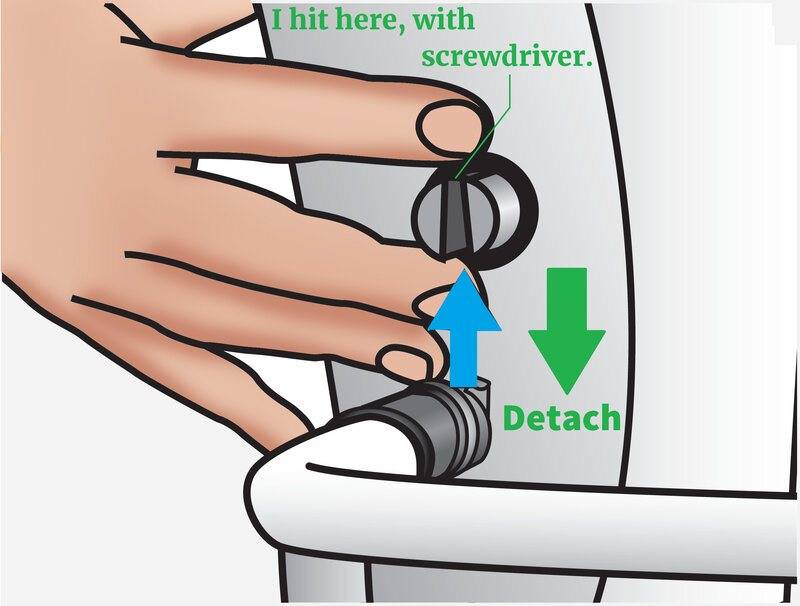

- One participant describes their struggle to loosen the slide while attempting to lift and push the chair components, indicating a need for a creative solution.

- Another participant questions whether the goal is to fully disassemble the chair or just to separate specific parts, suggesting a review of the assembly manual for clarity on the "click" mechanism.

- A third participant compares the mechanism to a snap ring on a shaft, proposing that squeezing the split shaft with pliers might help in removing it.

- Suggestions include using WD40 for lubrication, cautioning against potential damage to textiles, and recommending a stronger tool for impact, although there is confusion about the appropriate tool name.

- One participant identifies the tool as a "punch," while another humorously suggests a need for sharpening a chisel instead.

Areas of Agreement / Disagreement

Participants present multiple competing views and methods for uncoupling the slide, with no consensus on the best approach or solution. The discussion remains unresolved regarding the most effective technique.

Contextual Notes

Limitations include unclear references to the assembly manual and the specific nature of the "click" mechanism, which may depend on the chair's design. The effectiveness of suggested methods is not confirmed.

Who May Find This Useful

Individuals facing similar challenges with office chair assembly or disassembly, as well as those interested in practical problem-solving techniques for mechanical issues.