meakerb

- 1

- 0

- TL;DR

- I am trying to size the two motors needed for a robot arm I'm building. The pivot point for one motor is (through two pulleys) at the end of an arm driven by another motor.

I am trying to size the two motors needed for a robot arm I'm building.

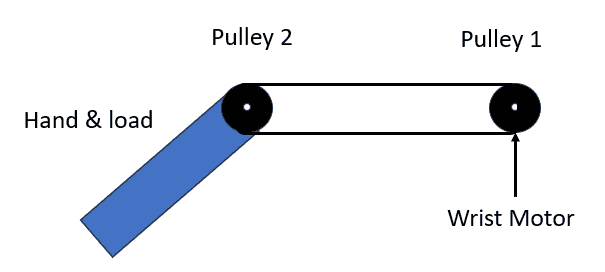

The first motor, which I call the wrist motor, drives a pulley on a fixed axis that connects to a second pulley (of the same size) which is attached to a hand and load.

I can calculate the moment of inertia for the hand and load about the axis of the second pulley, and therefore calculate the required torque for the wrist motor.

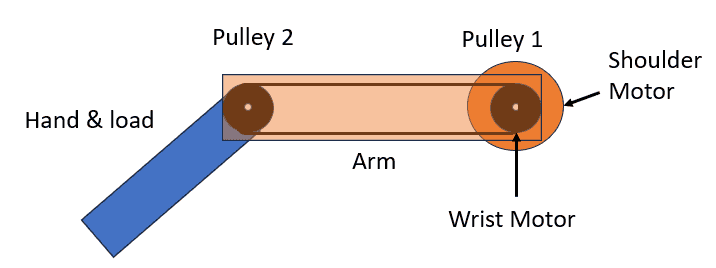

However, the second motor, which I call the shoulder motor, also rotates on the same fixed axis as the wrist motor, but it rotates an arm that holds the second pulley.

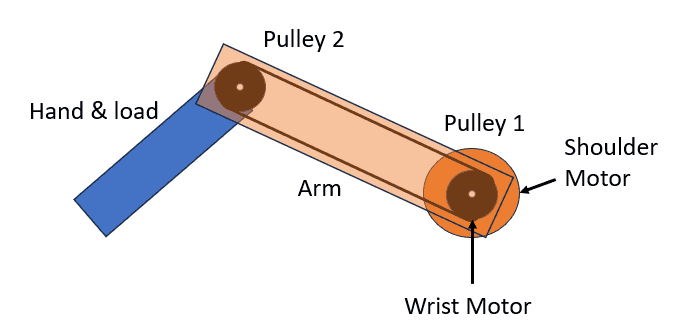

The first diagram, and my calculation for required torque for the wrist motor, assumed the shoulder motor was fixed (thereby fixing the axis of pulley 2). To calculate the required torque of the shoulder motor, do I assume that the wrist motor is fixed and use the parallel axis theroem for the moi of the hand & load, plus the moi of the arm? This doesn't seem right to me since, if the wrist motor is fixed, the gearing effect of the two pulleys will keep the hand & load at the same relative angle to the ground.

In reality, both motors will be moving at the same time. Any insight is greatly appreciated.

The first motor, which I call the wrist motor, drives a pulley on a fixed axis that connects to a second pulley (of the same size) which is attached to a hand and load.

I can calculate the moment of inertia for the hand and load about the axis of the second pulley, and therefore calculate the required torque for the wrist motor.

However, the second motor, which I call the shoulder motor, also rotates on the same fixed axis as the wrist motor, but it rotates an arm that holds the second pulley.

The first diagram, and my calculation for required torque for the wrist motor, assumed the shoulder motor was fixed (thereby fixing the axis of pulley 2). To calculate the required torque of the shoulder motor, do I assume that the wrist motor is fixed and use the parallel axis theroem for the moi of the hand & load, plus the moi of the arm? This doesn't seem right to me since, if the wrist motor is fixed, the gearing effect of the two pulleys will keep the hand & load at the same relative angle to the ground.

In reality, both motors will be moving at the same time. Any insight is greatly appreciated.