kore52

- 3

- 0

- TL;DR

- hydraulic requirements for liftgate actuators/cylinders

Hello everyone and thanks for any and all feedback!

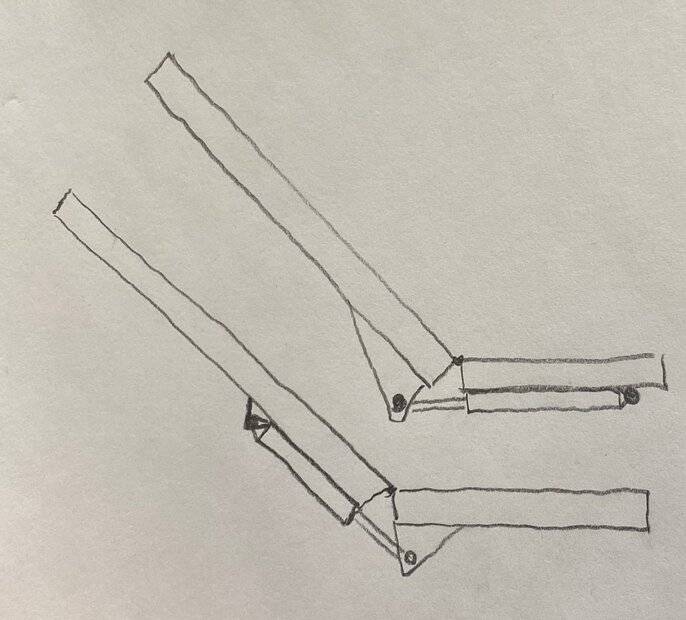

I am looking for help with a hydraulic system for a liftgate conveyor I will be installing for a customer. The conveyor is 10" in length and 3' wide but the liftgate portion is only 7' long. The approx. weight of the 7' section 500lbs. My questions is what hydraulic cylinders would i need to rotate/lift the 7' section 90 degrees?

I am looking for help with a hydraulic system for a liftgate conveyor I will be installing for a customer. The conveyor is 10" in length and 3' wide but the liftgate portion is only 7' long. The approx. weight of the 7' section 500lbs. My questions is what hydraulic cylinders would i need to rotate/lift the 7' section 90 degrees?