- #1

vin300

- 603

- 4

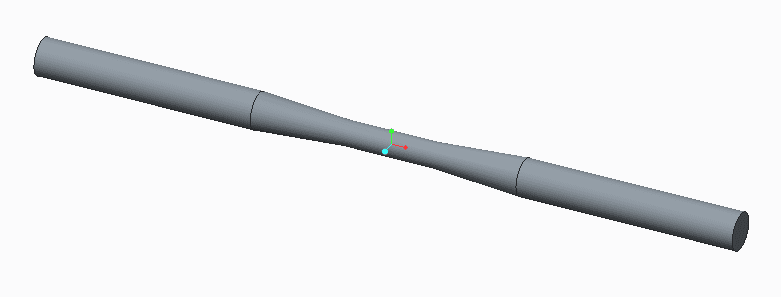

Below is a part proposed to be manufactured. The inspection of this part poses a problem, because vernier callipers only measure distances between parallel surfaces.

I know there is some photographic method of measuring distances, however I would like to know is there no way of physically measuring the diameter along the curvature.

I know there is some photographic method of measuring distances, however I would like to know is there no way of physically measuring the diameter along the curvature.