pyroartist

- 50

- 6

- TL;DR

- Something that has the same effect as a rack and pinion but does not involve gear teeth. Maybe made with levers.

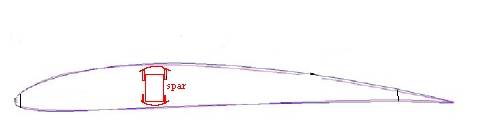

I am not very good at visualizing mechanisms and how they work. I just looked at all the mechanisms at http://507movements.com/. This is a fun little website and some of the mechanisms have been animated so you can better see how they function. I am trying to build a sailboat wing with reversible camber for opposite tacks in which I can simply pull a lever or rope to reverse the camber. This would activate some mechanisms at about 15 places (a foot apart) along the main spar and push the semi-rigid double surface wing outward on one side and allow the wing to flatten against the spar on the other side. Then on the opposite tack the positions reverse and the other side of the wing is pushed outward to camber it.

I have tried in the past to use sliding rods and have the wind flatten one side and push the rods over to create the camber but it did not work well.

A rack and pinion would achieve this motion as the rack moves from side to side. But teeth are too difficult to make and gears are heavy. I would like some sort of simple arrangement of levers and linkages that would do the same thing. I can visualize an arm swinging into position to push the wing out while the other side swings in so that the "pushing surface" folds down to nearly flat against the spar. These arms would be mounted onto the rectangular main spar. All 15 positions must be tied together with very little play in the motion. See my crude sketch attached. Thanks for any ideas. (There will be other internal structures not shown here.)

I have tried in the past to use sliding rods and have the wind flatten one side and push the rods over to create the camber but it did not work well.

A rack and pinion would achieve this motion as the rack moves from side to side. But teeth are too difficult to make and gears are heavy. I would like some sort of simple arrangement of levers and linkages that would do the same thing. I can visualize an arm swinging into position to push the wing out while the other side swings in so that the "pushing surface" folds down to nearly flat against the spar. These arms would be mounted onto the rectangular main spar. All 15 positions must be tied together with very little play in the motion. See my crude sketch attached. Thanks for any ideas. (There will be other internal structures not shown here.)