gnurf

- 370

- 8

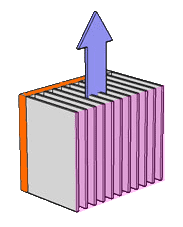

It has been suggested to me that the ability of the heatsink shown below to remove heat from its base (orange) by natural convection could be enhanced by closing the open side (pink) shown in the figure below. Assume a lid (pink) of non-conductive/isolating material. I think the idea is that this would induce a "chimney" effect that would increase the pressure gradient along the fin lengths and thus increase the rate at which warm air is removed.

To me, the idea that artificially limiting the system's access to cold air would somehow have a net cooling effect seems, at the very least, counter-intuitive and although there are some google-hits that sort-of suggest that this is a thing, I've never seen a closed fin design like that and I suspect that is for a reason.

Comments or pointers to fundamental principles are appreciated.

To me, the idea that artificially limiting the system's access to cold air would somehow have a net cooling effect seems, at the very least, counter-intuitive and although there are some google-hits that sort-of suggest that this is a thing, I've never seen a closed fin design like that and I suspect that is for a reason.

Comments or pointers to fundamental principles are appreciated.