- #1

Hammad

- 22

- 1

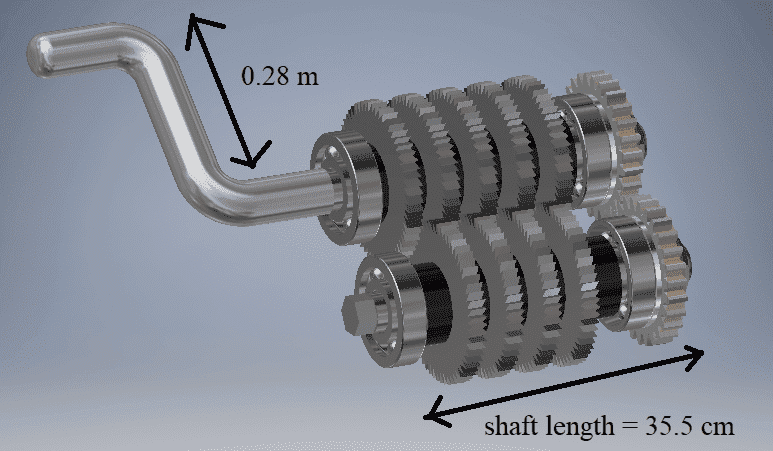

this is my design

i want to calculate its various stress and forces. since the bottle is being cut, i think there is perpendicular force upwards, how do i calculate this cutting shear force?

1) force and stress applied by cutting blade on the plastic bottle

2) force moment and stress applied on the rotating shaft with blades.

3) force required to exert on the hand to shred the plastic bottle

4) diameter of shaft for safe design

5) forces, stress and moment at the bearings.

6) what boundary conditions i need to apply for shaft and the handle?

etc

these are the following calculations i have done

Link: https://www.pdf-archive.com/2018/05/01/shredder-calculations/

can you please guide me on this

thanks

i want to calculate its various stress and forces. since the bottle is being cut, i think there is perpendicular force upwards, how do i calculate this cutting shear force?

1) force and stress applied by cutting blade on the plastic bottle

2) force moment and stress applied on the rotating shaft with blades.

3) force required to exert on the hand to shred the plastic bottle

4) diameter of shaft for safe design

5) forces, stress and moment at the bearings.

6) what boundary conditions i need to apply for shaft and the handle?

etc

these are the following calculations i have done

Link: https://www.pdf-archive.com/2018/05/01/shredder-calculations/

can you please guide me on this

thanks

Attachments

Last edited: