SUMMARY

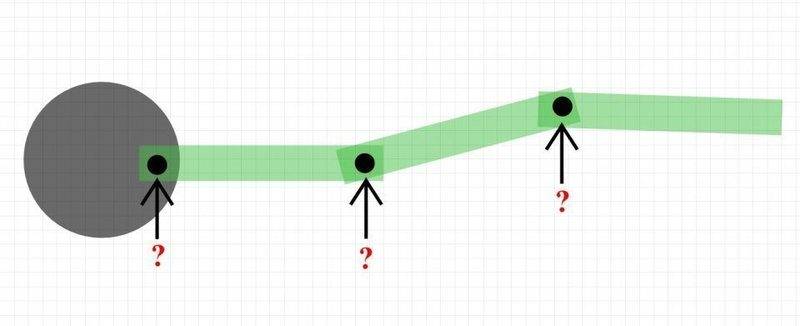

This discussion focuses on optimizing movable joint parts for slider crank mechanisms, specifically addressing the types of bolts and nuts suitable for constructing these joints. The recommended components include shoulder bolts, which are hardened and ground to precise tolerances, and nylon lock nuts for initial assembly. For enhanced security under heavy loads, alternatives such as castle nuts with cotter pins or stover nuts are suggested. The conversation emphasizes the importance of selecting the right fasteners to ensure stability and durability in mechanical applications.

PREREQUISITES

- Understanding of slider crank mechanisms

- Familiarity with fasteners, specifically shoulder bolts and nylon lock nuts

- Knowledge of mechanical load considerations

- Basic principles of mechanical assembly and joint design

NEXT STEPS

- Research the specifications and applications of shoulder bolts

- Learn about the use of castle nuts and cotter pins in mechanical assemblies

- Explore the properties and benefits of stover nuts for high-vibration environments

- Investigate alternative joint designs for slider crank mechanisms

USEFUL FOR

Mechanical engineers, hobbyists building robotic arms, and anyone involved in designing or optimizing slider crank mechanisms will benefit from this discussion.