FEAnalyst

- 348

- 149

- TL;DR

- How to perform analytical stress analysis of a quick return mechanism?

Hi,

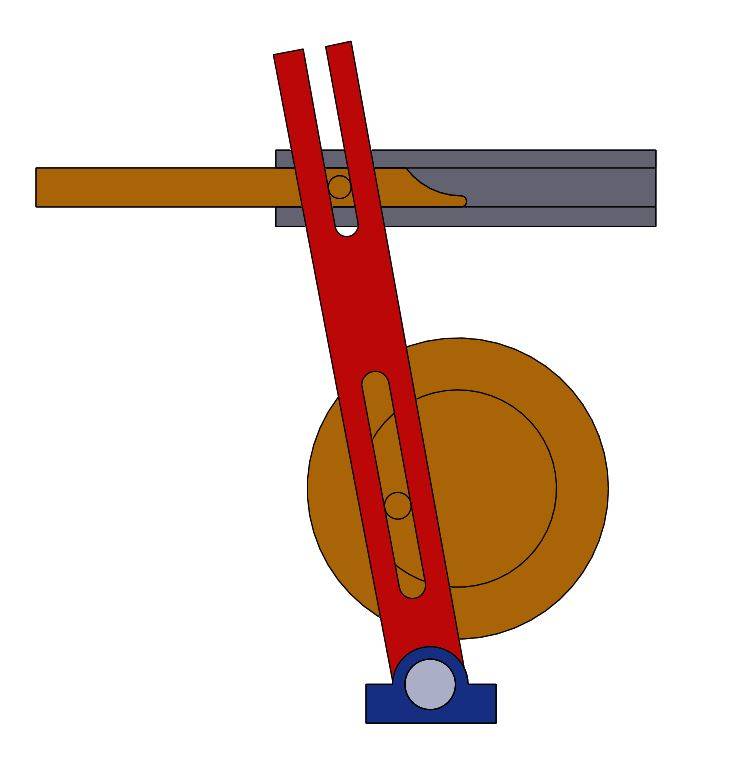

I wonder how to approach stress analysis of quick return mechanism used in shaper machines (see the diagram below):

The first issue is: which moment in the working process of this mechanism should be used for analysis (when will the mechanism experience largest loads)? So far I assumed that it will happen with maximum extension of the tool (like in the picture above).

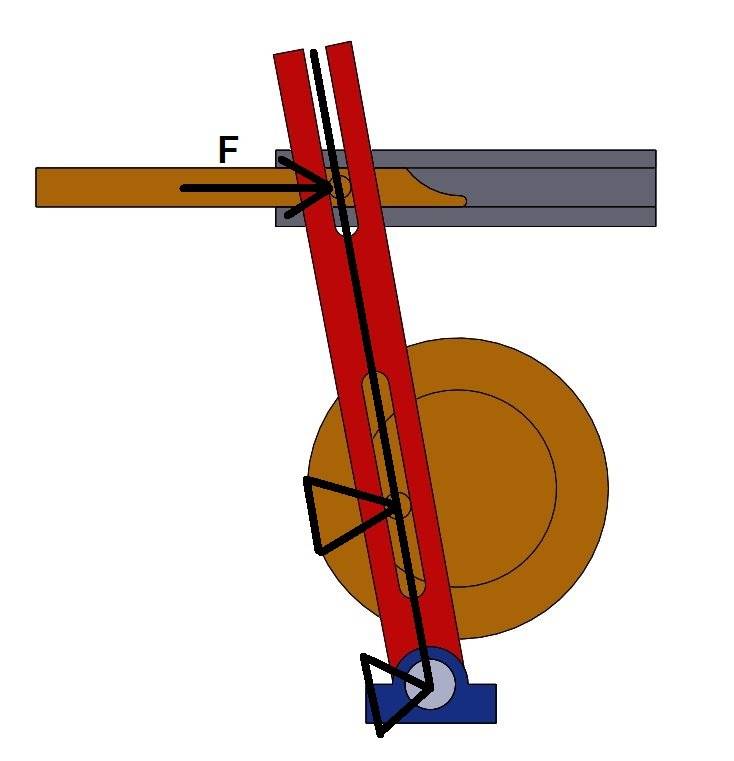

The second issue is: how to simplify this mechanism for analytical stress calculations (I can use FEA but it's not what I want to achieve now)? My current idea is to treat this red arm as a beam supported at two points and assume that the mechanism is subjected only to reaction force from the tool that presses on the workpiece:

Is this approach correct? Or should I do it differently - if yes then how? And what about the remaining parts of the mechanism - how to analyze them in terms of strength?

I've searched the literature but I've only found kinematic studies of such mechanisms. Nothing about stress analyses.

Thanks in advance for your help.

I wonder how to approach stress analysis of quick return mechanism used in shaper machines (see the diagram below):

The first issue is: which moment in the working process of this mechanism should be used for analysis (when will the mechanism experience largest loads)? So far I assumed that it will happen with maximum extension of the tool (like in the picture above).

The second issue is: how to simplify this mechanism for analytical stress calculations (I can use FEA but it's not what I want to achieve now)? My current idea is to treat this red arm as a beam supported at two points and assume that the mechanism is subjected only to reaction force from the tool that presses on the workpiece:

Is this approach correct? Or should I do it differently - if yes then how? And what about the remaining parts of the mechanism - how to analyze them in terms of strength?

I've searched the literature but I've only found kinematic studies of such mechanisms. Nothing about stress analyses.

Thanks in advance for your help.