SUMMARY

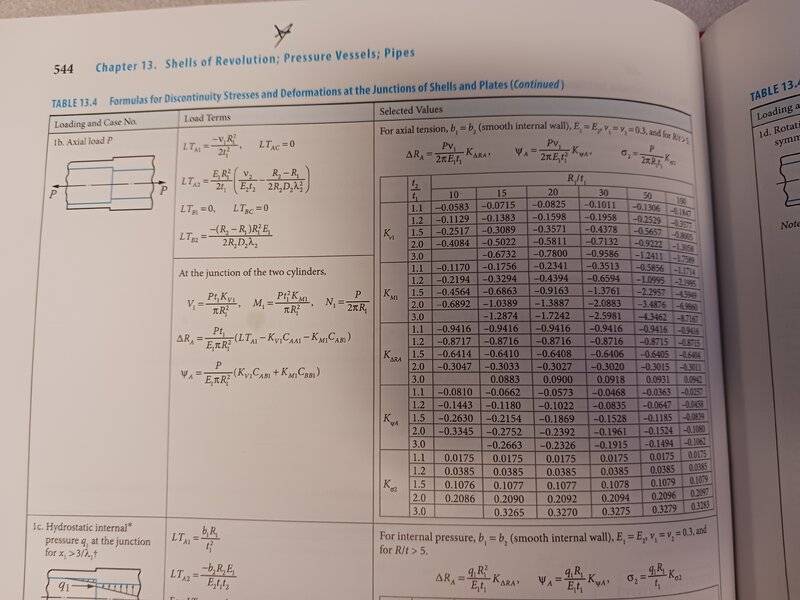

The discussion clarifies the meaning of R_A in Roark's Formulas for Stress and Strain 9E, specifically in Table 13.4 on page 543. R_A is defined as the radius of common circumference, representing the intersection of the midsurfaces of two different shells, rather than any shared radius. When the left section is not curved, R_A equals R_1; however, if it is more circular, R_A is calculated as R_1 multiplied by the sine of the angle, measured vertically. It is important to note that R_A should not be confused with delta R_A, which appears in the referenced table.

PREREQUISITES

- Understanding of Roark's Formulas for Stress and Strain 9E

- Familiarity with stress analysis concepts

- Knowledge of cylindrical shell theory

- Basic trigonometry for calculating R_A

NEXT STEPS

- Review Roark's Formulas for Stress and Strain 9E, focusing on Table 13.4

- Study cylindrical shell theory and its applications in engineering

- Learn about the calculation of intersection points in structural analysis

- Explore advanced stress analysis techniques for composite materials

USEFUL FOR

Engineers, particularly those specializing in structural analysis and materials science, will benefit from this discussion, as well as students studying mechanical engineering principles related to stress and strain in cylindrical structures.