sempiternum

- 3

- 0

Hi. I'm working in the design of an auotomatic bar feeder for a CNC lathe. I've established that the bars will not be longer than 1.2 m and will not have a diameter of more than 75 mm. Suppose they are steel bars, which would make them have a mass of about 80 kg

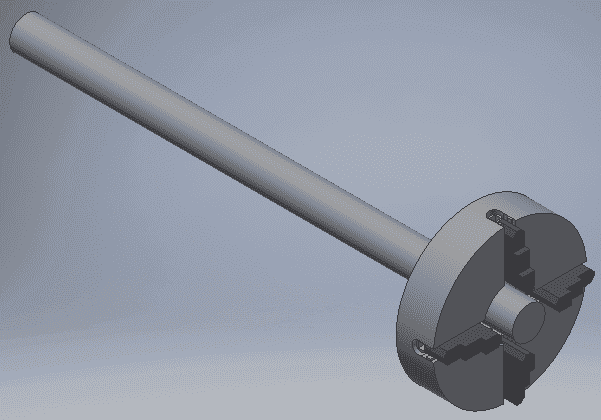

So, bars are tightly held in one end by the lathe chuck, as shown in this image

Now, on the other end there'll be the automatic feeder. When the chuck starts to rotate to, let's say 1000 RPM, the free end will not naturally stay centered, so, I need to calculate the magnitude of the force created by the vibration on the free end as to design the components that will hold it steady.

How can I approach this calculation?

Thanks.

So, bars are tightly held in one end by the lathe chuck, as shown in this image

Now, on the other end there'll be the automatic feeder. When the chuck starts to rotate to, let's say 1000 RPM, the free end will not naturally stay centered, so, I need to calculate the magnitude of the force created by the vibration on the free end as to design the components that will hold it steady.

How can I approach this calculation?

Thanks.