Guineafowl

- 876

- 409

Hi all,

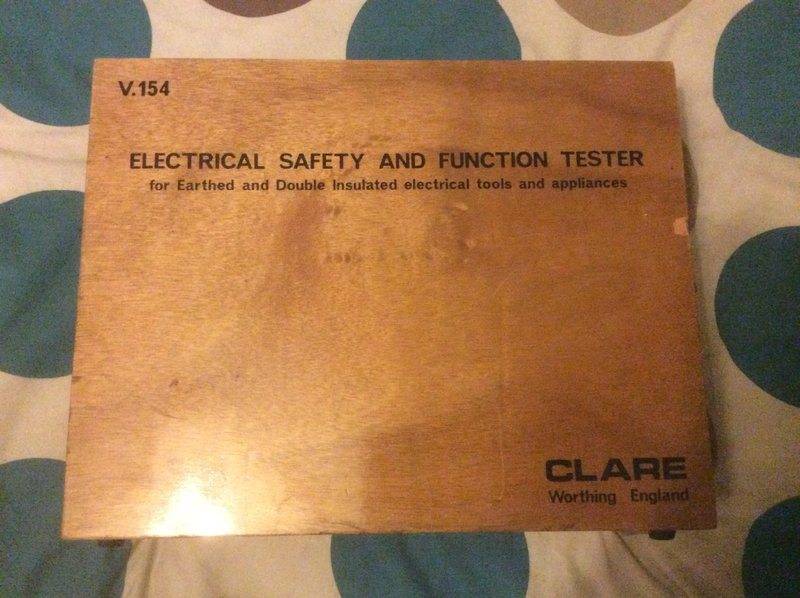

An interesting old device for you, circa 1984. It comes in a nicely varnished plywood cabinet:

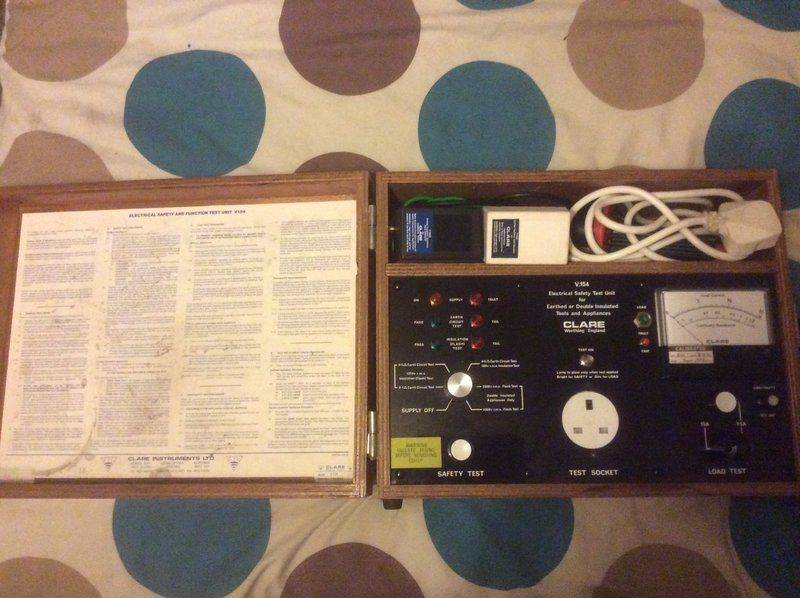

To restore it, I had to do some cabinetry to fix some broken seams, and a relay had gone bad inside. All working now.

On the inner lid is a sheet with full operating instructions. On the right is the tester itself, with a neat compartment for the test leads:

The unit switches on with a satisfying ‘clunk’ of a relay, and the upper orange neon glows to show the power supply is OK. You plug the DUT into the socket, connect the flying Earth lead to its metalwork (if applicable) and select:

0.1ohm Earth circuit test/1250V flash:

First applies 8 Vac at 26 amps through the appliance’s Earth circuit. Displays Earth path resistance on meter. Then applies 1250V between L+N to Earth to check insulation resistance. If all is well, the two green pass neons glow.

0.5 ohm Earth circuit test:

Same as above, but only 10 A through Earth path and allows up to 0.5 ohm resistance there. For appliances with long leads.

0.5 ohm Earth circuit test/500V IR test:

Again, a gentler Earth test and only 500V IR test for delicate appliances.

3000 and 4000V Flash test:

Applies these voltages between L+N and the high voltage probe (see below). You probe any metalwork on the (double insulated) appliance to check for flashover. If so, the machine will cut the test short and the lower right fault lamp will glow. Sparks and crackling happen while you’re doing this.

The load test switch activates a contactor and actually runs the appliance, so you can check the current is within spec. A 16A trip is present. The button above divides the scale by 10 for smaller appliances.

Showing the probe, Earth clip and two fault simulator plugs.

Hope this is interesting to someone - it was hard to find info online about the machine, so that pasted instruction sheet was very useful. It’s so much more fun testing an appliance with this - the clunks and clicks, the glowing lamps - you really feel like you’re doing something. Better than a modern tester which is just plug in, press test, BEEP.

Hope this is interesting to someone - it was hard to find info online about the machine, so that pasted instruction sheet was very useful. It’s so much more fun testing an appliance with this - the clunks and clicks, the glowing lamps - you really feel like you’re doing something. Better than a modern tester which is just plug in, press test, BEEP.

An interesting old device for you, circa 1984. It comes in a nicely varnished plywood cabinet:

To restore it, I had to do some cabinetry to fix some broken seams, and a relay had gone bad inside. All working now.

On the inner lid is a sheet with full operating instructions. On the right is the tester itself, with a neat compartment for the test leads:

The unit switches on with a satisfying ‘clunk’ of a relay, and the upper orange neon glows to show the power supply is OK. You plug the DUT into the socket, connect the flying Earth lead to its metalwork (if applicable) and select:

0.1ohm Earth circuit test/1250V flash:

First applies 8 Vac at 26 amps through the appliance’s Earth circuit. Displays Earth path resistance on meter. Then applies 1250V between L+N to Earth to check insulation resistance. If all is well, the two green pass neons glow.

0.5 ohm Earth circuit test:

Same as above, but only 10 A through Earth path and allows up to 0.5 ohm resistance there. For appliances with long leads.

0.5 ohm Earth circuit test/500V IR test:

Again, a gentler Earth test and only 500V IR test for delicate appliances.

3000 and 4000V Flash test:

Applies these voltages between L+N and the high voltage probe (see below). You probe any metalwork on the (double insulated) appliance to check for flashover. If so, the machine will cut the test short and the lower right fault lamp will glow. Sparks and crackling happen while you’re doing this.

The load test switch activates a contactor and actually runs the appliance, so you can check the current is within spec. A 16A trip is present. The button above divides the scale by 10 for smaller appliances.

Showing the probe, Earth clip and two fault simulator plugs.