Discussion Overview

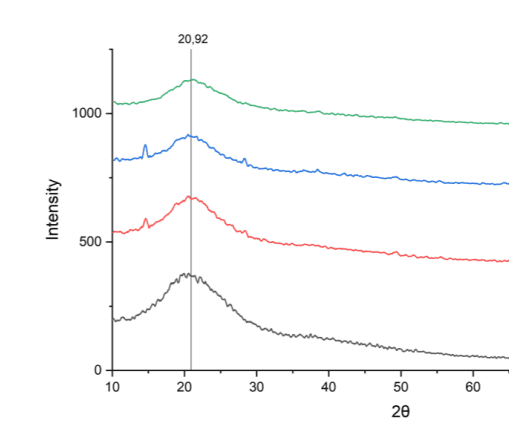

The discussion revolves around the interpretation of a broad peak observed at 2θ = 20.92° in X-ray diffraction (XRD) analysis of a polymer specimen. Participants explore the implications of this peak in relation to the crystallinity of the material, particularly in the context of adding fillers.

Discussion Character

- Exploratory

- Technical explanation

- Debate/contested

Main Points Raised

- One participant notes that the broad peak typically indicates amorphous material and questions whether the addition of filler makes the material "more amorphous."

- Another participant asks for clarification on the different colored traces in the XRD results and inquires about the specific filler used, suggesting that the material appears amorphous.

- A participant identifies the composition of the material as Chitosan + PEO + LiClO4 with added Al2O3, observing that the peak becomes broader with increasing filler content and seeks to understand its correlation to crystallinity.

- One participant mentions an evaluation using an image processing program, indicating that while the peak widths remain identical, their amplitudes decrease with added filler, suggesting that the filler may be scattering X-rays and affecting the baseline.

- A participant questions the source of the broad peak and notes the difficulty in separating the effects of the polymer and filler due to the stacking of traces on the intensity axis, proposing the need for additional baseline data for clearer analysis.

Areas of Agreement / Disagreement

Participants generally agree that the broad peak is indicative of amorphous characteristics in the material. However, there is no consensus on the implications of the peak broadening with added filler, and multiple views on the analysis and interpretation of the data remain present.

Contextual Notes

There are limitations regarding the interpretation of the XRD results, including the dependence on the baseline references and the need for additional data to isolate the effects of the filler from the polymer.