- #1

Apple&Orange

- 30

- 2

Hi everyone!

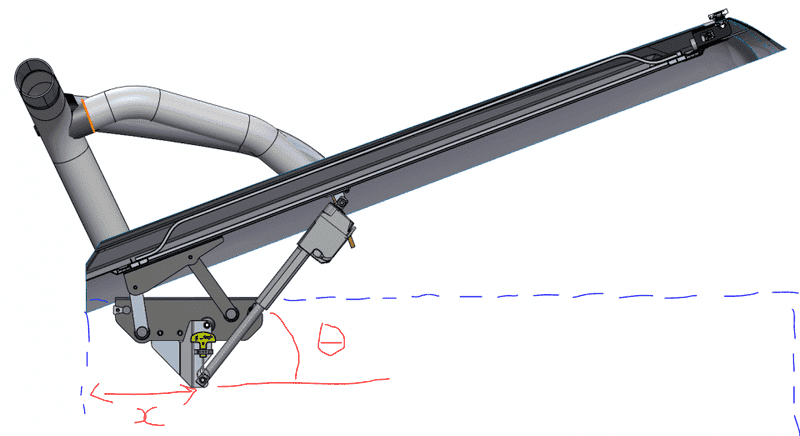

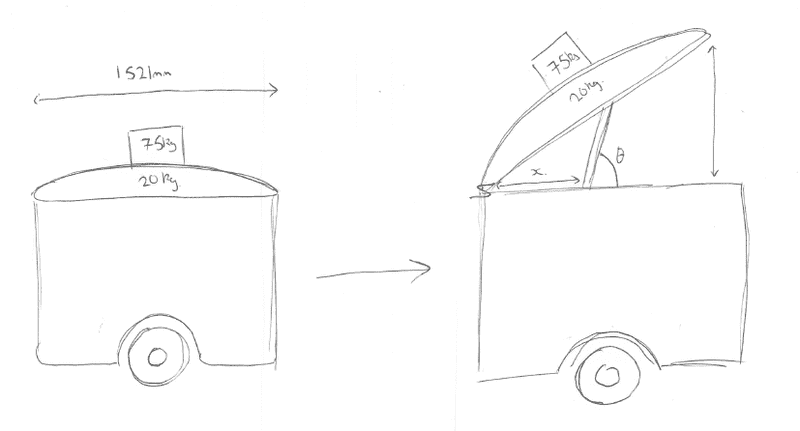

So I'm working on project where I have to design a hinge system for a hard lid that is fitted onto the back of a pickup truck.

In this system, I will be using 2x linear actuator(s) that will need to lift a total weight of roughly 95kg.

At the moment, I've got a selection of 600N, 900N, and 1200N single actuators to choose from.

In the past, I would figure the ideal position for the actuator via experimentation. However, I would like to tackle this problem through a more calculative approach. Having said this though...it has been a while since I've done any form of engineering calculation, and would greatly appreciate it if someone could point me in the right direction.

From memory though, it seems like I would need to calculate the shear force and bending moment?

Cheers

So I'm working on project where I have to design a hinge system for a hard lid that is fitted onto the back of a pickup truck.

In this system, I will be using 2x linear actuator(s) that will need to lift a total weight of roughly 95kg.

At the moment, I've got a selection of 600N, 900N, and 1200N single actuators to choose from.

In the past, I would figure the ideal position for the actuator via experimentation. However, I would like to tackle this problem through a more calculative approach. Having said this though...it has been a while since I've done any form of engineering calculation, and would greatly appreciate it if someone could point me in the right direction.

From memory though, it seems like I would need to calculate the shear force and bending moment?

Cheers