SevenToFive

- 56

- 3

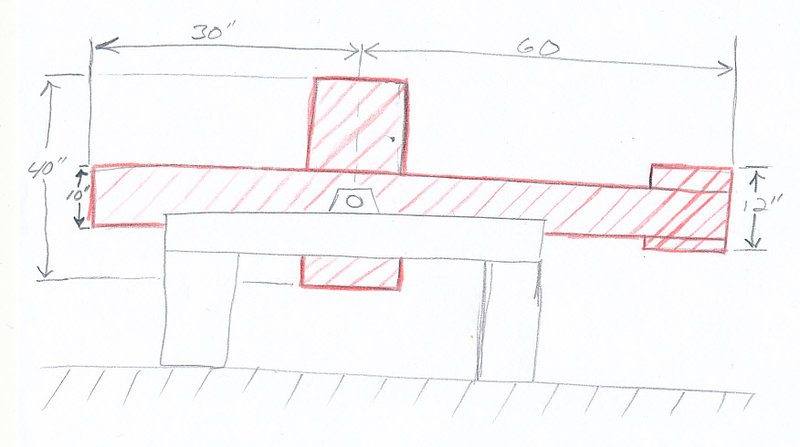

The red section of this fixture rotates 90 degrees it weighs 3600lbs, and is 130 inches wide. It is made out of 10 inch steel channel. On the left of the drawing is the dimension of 40" and the pivot point is actually in the center.

We can rotate it by hand if you grab onto the end that is 12" and it takes approximately 30lbs force applied to the end. If we want to add a gearbox to drive this fixture would it simply be multiplying the 30lbs by 60 inches that is the end of the fixture to the pivot point? Giving me 1800 in-lbs? It doesn't seem like enough. Or am I just greatly over simplifying this? Any help is greatly appreciated.

We can rotate it by hand if you grab onto the end that is 12" and it takes approximately 30lbs force applied to the end. If we want to add a gearbox to drive this fixture would it simply be multiplying the 30lbs by 60 inches that is the end of the fixture to the pivot point? Giving me 1800 in-lbs? It doesn't seem like enough. Or am I just greatly over simplifying this? Any help is greatly appreciated.