uppityd

- 5

- 0

At the risk of waiting hours on simulations of a sensor, I was wondering if I could use infinite element domain on COMSOL to simplify it.

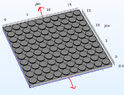

The first image consists of what I would like to simulate but found out that the simulation time is a huge factor as I have a lot to simulations to conduct. It describes axial stress on the sensor in opposite directions to encourage buckling and see the extent of it.

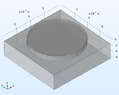

What I hope is to use one sensor node and apply an infinite element domain to it.

The problem is that I am not entirely sure how to do this.

The first image consists of what I would like to simulate but found out that the simulation time is a huge factor as I have a lot to simulations to conduct. It describes axial stress on the sensor in opposite directions to encourage buckling and see the extent of it.

What I hope is to use one sensor node and apply an infinite element domain to it.

The problem is that I am not entirely sure how to do this.