Loochia

- 2

- 1

Summary: Help!

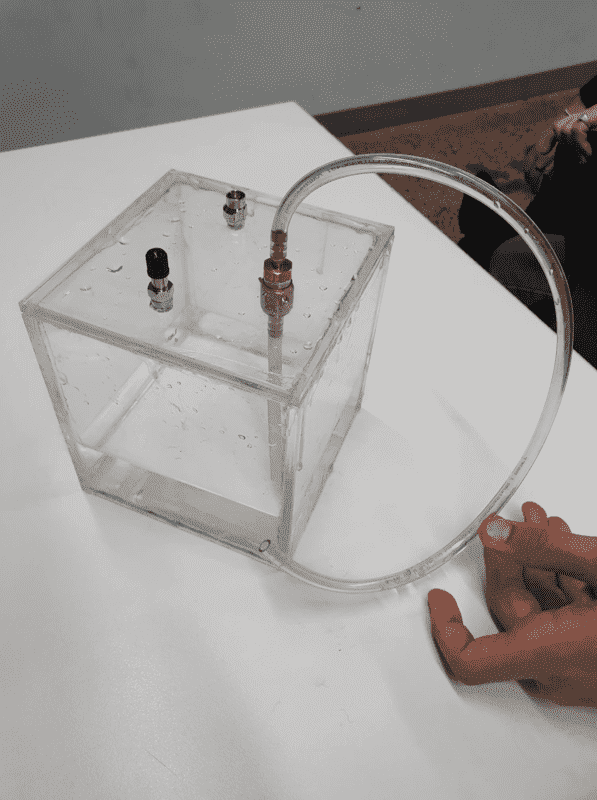

For my freshman engineering in design class, my group is trying to make an airtight tank that can withstand some pressure that is pumped in. For our prototype, we built a tank out of acrylic sheets and glued it together with epoxy glue, but it popped the second we pumped a little air inside. Does anyone have any suggestions as to other methods of created an airtight tank? Different materials, glues, etc?

For my freshman engineering in design class, my group is trying to make an airtight tank that can withstand some pressure that is pumped in. For our prototype, we built a tank out of acrylic sheets and glued it together with epoxy glue, but it popped the second we pumped a little air inside. Does anyone have any suggestions as to other methods of created an airtight tank? Different materials, glues, etc?