- #1

Delia

- 1

- 0

- TL;DR Summary

- Try to find parts from post-treatment of diesel engine gas

Hi folks,

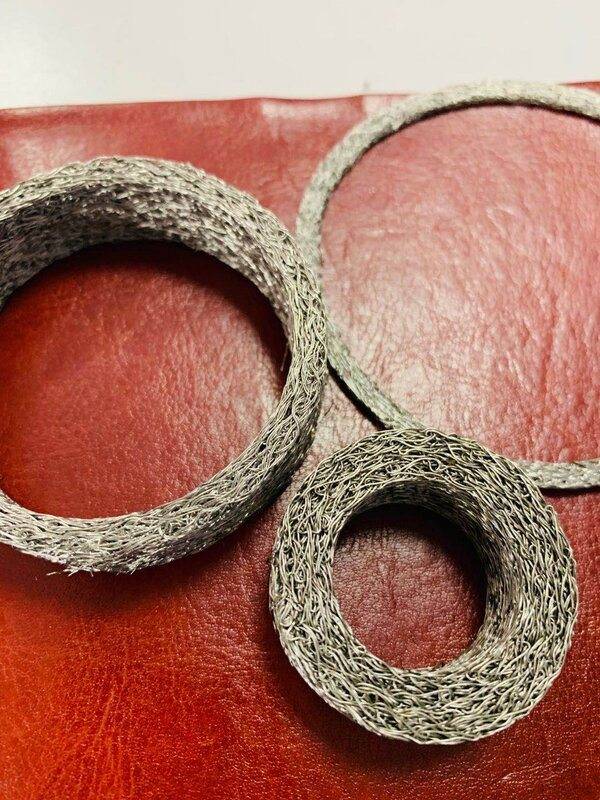

Any idea about what is it?

I am required to find parts like these items which are made of stainless steel 304 and used on the post-treatment of diesel engine gas.

Any idea about what is it?

I am required to find parts like these items which are made of stainless steel 304 and used on the post-treatment of diesel engine gas.

Last edited by a moderator: