- #1

Dorea

- 28

- 1

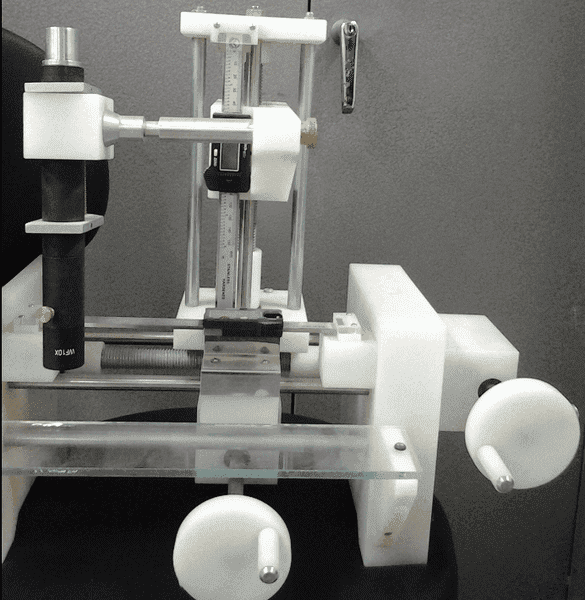

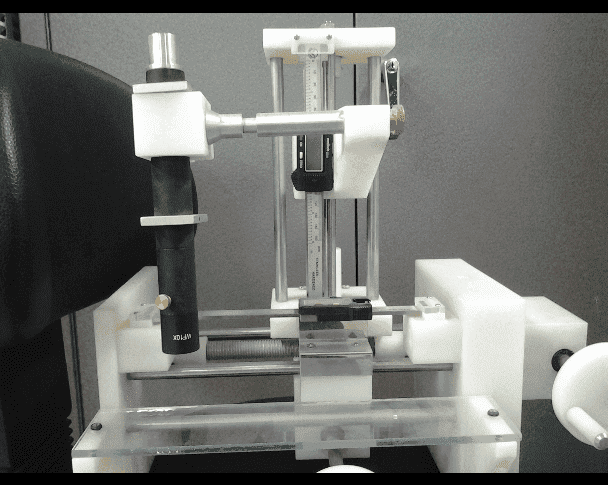

Does anybody know what is this device name and its application:

(It's in our optics laboratory)

(It's in our optics laboratory)

I'd agree, pending a look at what appears to be the microscope. It could be a laser or electron gun for all I know.jedishrfu said:It looks like a microscope that can measure exact/calibrated positioning and depth?

It just occurred to me to google WF10X:DaveC426913 said:I'm more curious about the business end of it. As in: where is it?

Does it all come down to the barrel on the left - everything else is scaffolding for adjustment?

What is the barrel pointed at? The glass plate?

Does the barrel have an eyepiece?

Does it magnify? Focus? Can you see anything if you put your eye to various eye-shaped parts of it?

Does the device still work if it's sitting on a different type of office chair?

Yes, that's why I said it looked like a microscope after googling the eyepiece. Also the eyepiece has a reticle for precise measurement as does the scaffolding.zoobyshoe said:It just occurred to me to google WF10X:

http://www.amscope.com/wf10x-microscope-eyepiece-with-reticle-23mm.html?gclid=CMLsmP6BvMECFYSPMgodTDkAWQ

Which turns out to be a microscope eyepiece. So, it looks like a microscope that's upside down.

I wonder if the whole barrel is upside-dozen or just the eyepiece.zoobyshoe said:It just occurred to me to google WF10X:

http://www.amscope.com/wf10x-microscope-eyepiece-with-reticle-23mm.html?gclid=CMLsmP6BvMECFYSPMgodTDkAWQ

Which turns out to be a microscope eyepiece. So, it looks like a microscope that's upside down.

Based on Zoob's description, it most certainly is.dlgoff said:I'm betting it's home-made.

No. Where? The only R/Y/B thing I see in the pic at all is the buttons on the digital calipers. Read Zoob's descrip in post #3.dlgoff said:Note the red, yellow, blue "light source"?

Thanks. Good to be back.dlgoff said:BTW Welcome back DaveC

I was wondering about that. Zoob suggested it moves in all three axes. I assumed perhaps the Y-axis is not visible, but that the bottom dial was for adjusting the Y-axis. The brass dial on the right at the top might have been for Z-axis adjustment.Doug Huffman said:The optical axis moves in two dimensions only.

Yes. I thought that odd. Why have a micrometer-accuracy adjustment on the Z-axis if the barrel can be moved freely as much as several inches?Doug Huffman said:The optical barrel may be free to move, suspended between the two square aluminum plates.

Precision ± 0.01 mm ? I'm very suspicious...DaveC426913 said:

I know, but I would trust here only to ± 0.1 mmDoug Huffman said:It's an industry standard device, perhaps the same model in my toolbox.

On closer inspection, I believe you're right. There is no Y axis movement. What looks like the Y axis crank is actually the Z axis crank, working through bevel gears in a box you can't see. There is a similar box on the right for the X axis lead screw. The Z lead screw is visible but mostly obscured by an upright structural rod. That rod obscuring the lead screw gave the lead screw the impression of being a rack such as you'd find on a height gage. I thought the Z axis must have some small, dedicated crank of its own that wasn't visible, which cranked a pinion up and down that rack.Doug Huffman said:The optical axis moves in two dimensions only. The glass plate is the stage for the subject. The adjustment crank first nearest the operator drives an unseen right-angle drive for the vertical motion adjustment. The optical barrel may be free to move, suspended between the two square aluminum plates.

Apparent depth in water. A simple experience!DaveC426913 said:...of what?

An optics device is a tool or instrument used to manipulate or measure light, such as lenses, mirrors, prisms, and filters.

The specific function of an optics device depends on its design and purpose. However, most optics devices work by interacting with light, either by bending or focusing it, or by filtering out certain wavelengths.

Some common types of optics devices include microscopes, telescopes, cameras, binoculars, and laser pointers.

Optics devices have a wide range of applications in everyday life, such as in eyeglasses, camera lenses, and traffic lights. They are also used in various industries, such as medicine, telecommunications, and manufacturing.

Yes, optics devices can be used for different purposes depending on their design and capabilities. For example, a telescope can be used for stargazing or for viewing distant objects on Earth, while a microscope can be used for examining small objects or organisms.