Kakashi

- 29

- 1

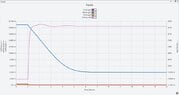

When Stream 1 flow rate is cut to nearly half of its design value, the flow control valve adjusts its output to maintain the process variable (PV) at the setpoint (SP). It reaches steady state about 6 minutes after the disturbance.

Since the circulating oil stream remains at its design flow, but the process stream it is cooling has now a lower flow the heat recovered by the oil reduced. As a result, the temperature rise is lower and the hot process stream is cooled to a lower temperature.

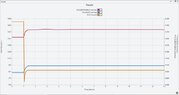

In the final HE, the process stream is cooled using cooling water. Now that both the process stream's flow rate and inlet temperature are lower, the temperature controller (TT) for Stream 5 attempts to maintain its outlet temperature at 40 °C by adjusting a valve. However, from the trend plot, the controller appears to respond quite slowly — it took nearly 7 hours to reach setpoint.Why might the temperature control response be so sluggish? Could it be due to poor controller tuning?

Another issue I noticed the pressure of Stream 5 decreased following the reduction in Stream 1 flow rate. With a lower pressure entering the flash drum, wouldn’t more volatile components be expected to vaporize, possibly reducing the liquid level instead of increasing it?. Also, the level controller output reaches 100%, but the PV (level fraction) is still only around 0.6 — well below the high limit of the controller range. Why does the controller saturate even though the level hasn’t hit its upper range?

For Stream 9 (the syngas stream), steady state was reached approximately 20 minutes after the disturbance, but at a higher temperature. I think this is because the lower flow rate and pressure of Stream 1 lead to a longer residence time in the heat exchanger, allowing more heat recovery. The heat duty of the reactor also decreased due to the reduced feed. Since the shell side of the reactor is simulated as a flash drum (V3), and we set its duty to zero, less energy is available to generate steam.

The amount of steam decreases rather if we set the duty of the drum to 0 excluding the heat from the reactor then heat is utilized to increase the temperature of bfw and generate less generate because its supplied at conditions of 240 C and 48 bar. I am not sure why the bfw flow rates is oscillating wildly in response to very small changes in the level fraction.

This leads to my final question: the boiler feed water (BFW) flowrate shows significant oscillations even though the level fraction in V3 barely changes. The fluctuations are large and continuous throughout the 12-hour period. Why would such small level changes cause such large swings in BFW flowrate? Could this be caused by overly aggressive controller tuning, or is there something else I might be missing?

Since the circulating oil stream remains at its design flow, but the process stream it is cooling has now a lower flow the heat recovered by the oil reduced. As a result, the temperature rise is lower and the hot process stream is cooled to a lower temperature.

In the final HE, the process stream is cooled using cooling water. Now that both the process stream's flow rate and inlet temperature are lower, the temperature controller (TT) for Stream 5 attempts to maintain its outlet temperature at 40 °C by adjusting a valve. However, from the trend plot, the controller appears to respond quite slowly — it took nearly 7 hours to reach setpoint.Why might the temperature control response be so sluggish? Could it be due to poor controller tuning?

Another issue I noticed the pressure of Stream 5 decreased following the reduction in Stream 1 flow rate. With a lower pressure entering the flash drum, wouldn’t more volatile components be expected to vaporize, possibly reducing the liquid level instead of increasing it?. Also, the level controller output reaches 100%, but the PV (level fraction) is still only around 0.6 — well below the high limit of the controller range. Why does the controller saturate even though the level hasn’t hit its upper range?

For Stream 9 (the syngas stream), steady state was reached approximately 20 minutes after the disturbance, but at a higher temperature. I think this is because the lower flow rate and pressure of Stream 1 lead to a longer residence time in the heat exchanger, allowing more heat recovery. The heat duty of the reactor also decreased due to the reduced feed. Since the shell side of the reactor is simulated as a flash drum (V3), and we set its duty to zero, less energy is available to generate steam.

The amount of steam decreases rather if we set the duty of the drum to 0 excluding the heat from the reactor then heat is utilized to increase the temperature of bfw and generate less generate because its supplied at conditions of 240 C and 48 bar. I am not sure why the bfw flow rates is oscillating wildly in response to very small changes in the level fraction.

This leads to my final question: the boiler feed water (BFW) flowrate shows significant oscillations even though the level fraction in V3 barely changes. The fluctuations are large and continuous throughout the 12-hour period. Why would such small level changes cause such large swings in BFW flowrate? Could this be caused by overly aggressive controller tuning, or is there something else I might be missing?