JCSS

- 4

- 0

- TL;DR

- Help with anchor and bolt sizing calcualtions

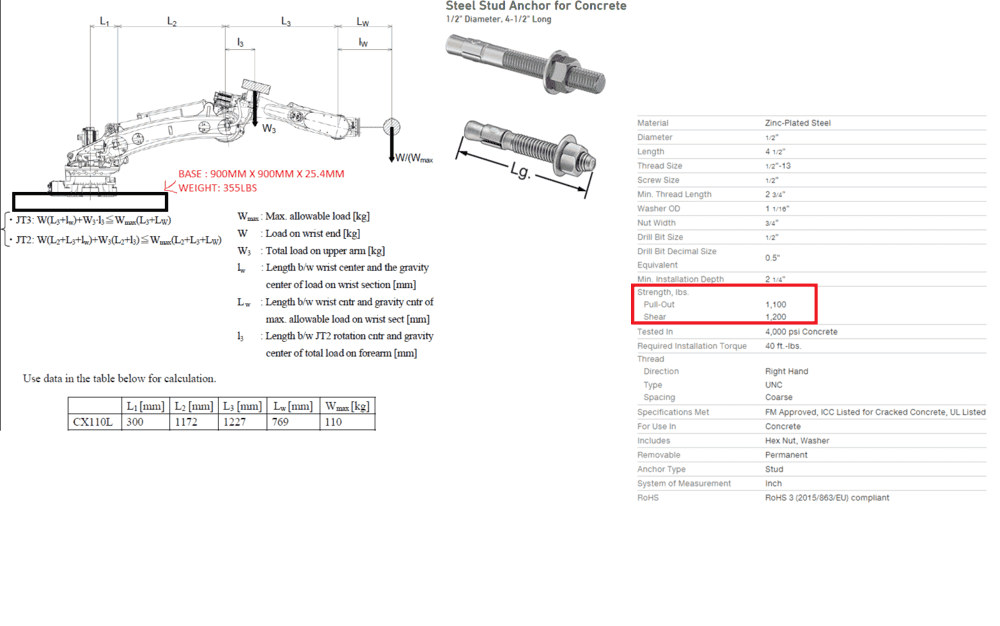

The robot weight is 900kg

I have a robot with max reach swinging around with a weight of 110kg at the end at 125 degree/s

I am not sure if the anchors I use are strong enough to hold it down assuming i mount the robot at the centre of the mounting plate

Any advice with doing calculations to do a sanity check?

I am also using M20 bolts to mount the robot to the base with 24mm thread engagement Class 12.9 bolts x 8 around the diameter Space around roughly at L1=300mm

Thanks

I have a robot with max reach swinging around with a weight of 110kg at the end at 125 degree/s

I am not sure if the anchors I use are strong enough to hold it down assuming i mount the robot at the centre of the mounting plate

Any advice with doing calculations to do a sanity check?

I am also using M20 bolts to mount the robot to the base with 24mm thread engagement Class 12.9 bolts x 8 around the diameter Space around roughly at L1=300mm

Thanks