- #1

LilEngineer

- 1

- 0

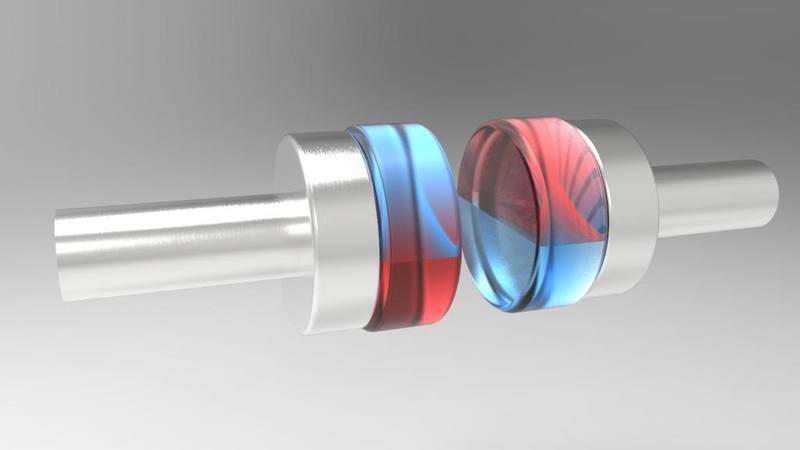

I'm just designing a simple magnetic clutch that i can can alter the Break-away force by changing the air gap between the two diametric magnets.

I guess I'm having a hard time understanding the practical difference between flux density, field strength and Force at a given distance of magnets… and how i apply the figures to my design.

As far as i understand, the flux density is measured from the cross sectional area through the magnet, and so an N52 will have a higher flux density than an N28 for neodymium magnets… but this is just relevant inside if the magnet.

However, when i look at data sheets for these magnets, the N28 appears to generate a greater force Fr for a given distance S than an Equivalent N52 magnet.

So if i want the strongest magnetic coupling and so the highest Break-away toque, am i right in saying that i should use N28 magnets?

thanks

I guess I'm having a hard time understanding the practical difference between flux density, field strength and Force at a given distance of magnets… and how i apply the figures to my design.

As far as i understand, the flux density is measured from the cross sectional area through the magnet, and so an N52 will have a higher flux density than an N28 for neodymium magnets… but this is just relevant inside if the magnet.

However, when i look at data sheets for these magnets, the N28 appears to generate a greater force Fr for a given distance S than an Equivalent N52 magnet.

So if i want the strongest magnetic coupling and so the highest Break-away toque, am i right in saying that i should use N28 magnets?

thanks