Noob of the Maths

- 52

- 6

- Homework Statement

- cyclic

- Relevant Equations

- ladder lenguage

HI! everyone :)

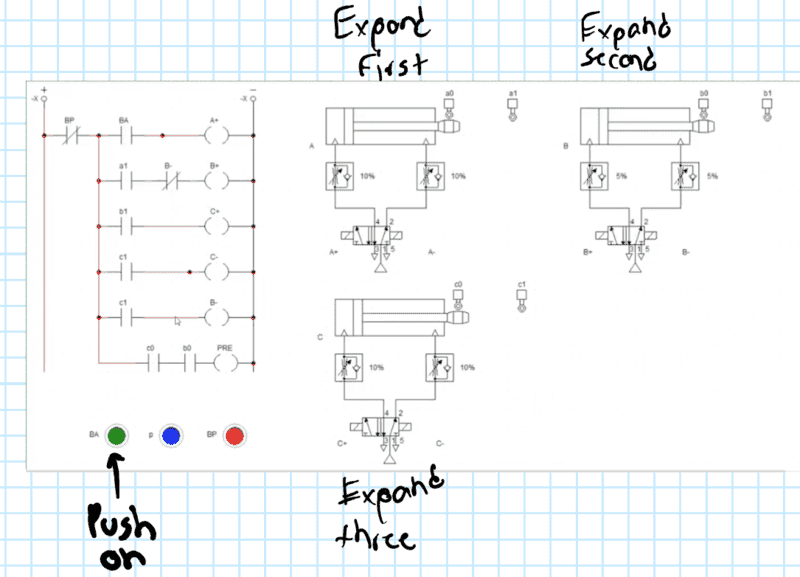

in today's electronics class the teacher asked us to make a simultaneous circuit of 3 pistons, with ladder language.

What am I supposed to do:

Upon energizing the circuit, they should expand one piston after the other; from A to C.

When piston C expands, it should return to its position by itself, and consecutively B and A in the same way.

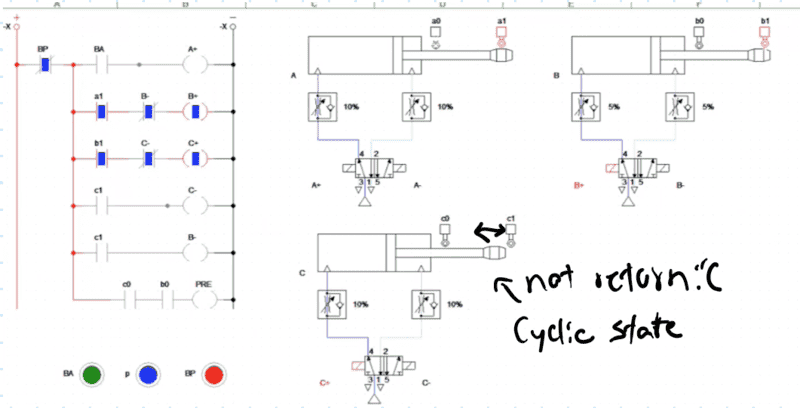

At first the circuit works by expanding, but when piston C retracts, it does not contract completely and returns to its position again and again. The circuit is in a cyclic state of no return.

Thanks for read:)

in today's electronics class the teacher asked us to make a simultaneous circuit of 3 pistons, with ladder language.

What am I supposed to do:

Upon energizing the circuit, they should expand one piston after the other; from A to C.

When piston C expands, it should return to its position by itself, and consecutively B and A in the same way.

At first the circuit works by expanding, but when piston C retracts, it does not contract completely and returns to its position again and again. The circuit is in a cyclic state of no return.

Thanks for read:)