Here are some comments about using fans to cool electronic equipment:

1) When fans work, they move air molecules and create a pressure difference across the fan. Too cool stuff you want lots of molecules. Usually one side of the fan is at ambient pressure, which won't change. So orient your fan to blow into the enclosure to make higher pressure. The other direction will be trying to make a vacuum inside the enclosure. Fans have a hard time collecting molecules from low pressure than higher pressure. You get (slightly) more mass flow.

2) As others have said, you may want to filter the dust. That dust has to flow through the fan, If the fan is oriented to pressurize the enclosure, you can filter the dust at the fan before it enters. In the "vacuum" configuration the filter needs to be away from the fan (at the inlet). However, often there are multiple paths that air can enter a vacuum (holes, seams, etc.), so it's harder to collect all of the dust if the filter isn't at the fan.

3) Usually I want to located the fan at the front panel of the equipment. This is where the humans are, and they normally have cleaner cooler air than the backside of the equipment. This is especially important if you equipment is located in a rack or with other equipment. Do not collect your air from a hot and dusty place.

4) Filters should be cleaned. If you hide the filter at the back, it will never be seen and never cleaned. On the front panel it is easy to clean and inspect.

5) Don't blow air in the operators face, they won't like it.

6) Think about noise. Your customer doesn't like that either.

7) Try to provide a low impedance path for the air flow before the inlet and after the exhaust. Design equipment so that it is unlikely for the user to do a stupid installation. Say this in the installation/operators manual. Put labels that say "do not block exhaust", etc.

8) Design your cooling to operate at high altitude (like Denver, not the stratosphere). Air cooling is a lot worse in Denver than in LA.

9) Select a fan technology that suits your airflow needs. Some fans are designed to operate well with high flow and low pressure drop, others are the opposite. Match the fan type to your configuration.

10) Did I say think about high altitude performance? Worth repeating... Just because it seems to work in Boston, doesn't mean it will be reliable in Denver; and you probably won't know why your products die early there. On the plus side, most of your market is at sea level.

11) Honestly, some low power products really don't need significant airflow. Sometimes you just need to avoid a sealed up oven. Some don't even really need a fan if you can arrange good convective cooling. None of this applies to them.

12) If you need good lifetime, or if your fan is big and works hard, then ball bearings are good. Expensive, but good.

13) For extra credit, in complex systems that monitor the tachometer on your fan. Test for really high speed too. That may mean you have no airflow because the inlet is blocked. Or not, it all depends on the details.

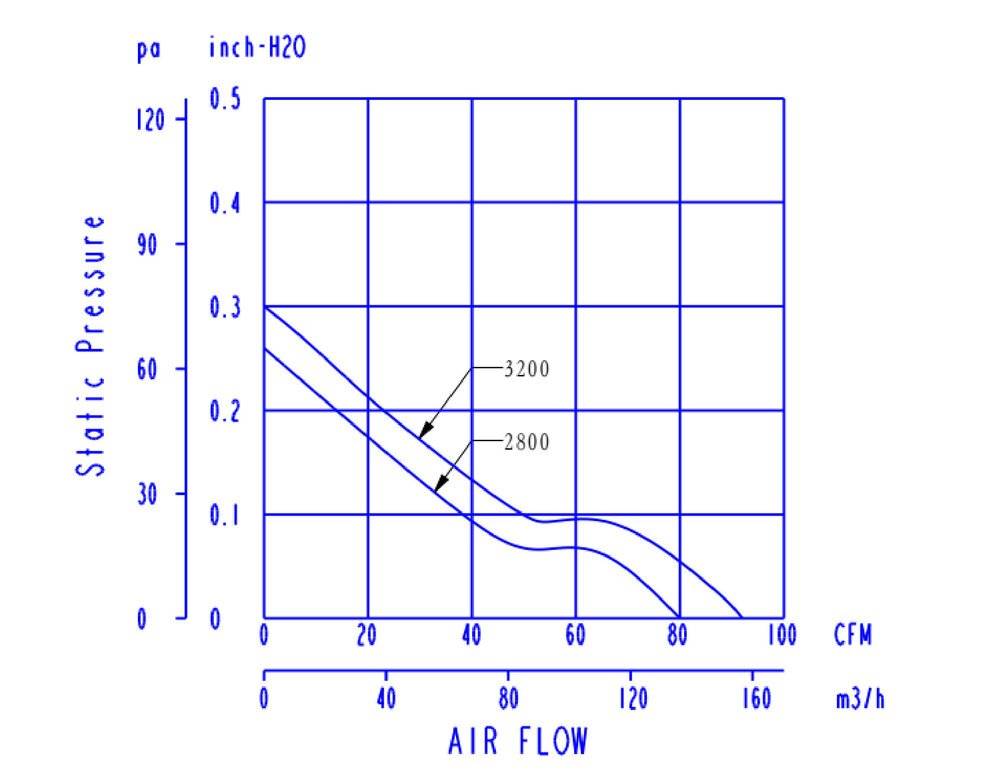

13) Your average axial fan's datasheet will have a curve like the one below (that's two fans, we'll focus on the good one). Of course what you want is maximum flow. What you have to deal with in the real world is the pressure drop needed to get that flow. Look for that kink in the flow pressure curve. That's where this fan will be working in a good design. If you need 80 CFM, this fan is scary, as soon as your filter gets dirty your transistor will fry. If you need 10 CFM, this fan is probably too expensive (not just cost; front panel space, enclosure size, etc.), unless you have a very restrictive system. You're enclosure has a pressure vs. flow curve too (probably a quadratic?) you can think of superimposing that enclosure curve over the fan curve to get the operating point. A nice theoretical idea, isn't it? We never actually have that data in the commercial world. But you could try a couple of different fans (really different) to get a couple of data points, then you invent the enclosure curve from that with some creative thinking and lab work. It's not a great design process but it's what we actually end up doing.