Roy S Ramirez

- 24

- 4

Hello everybody!

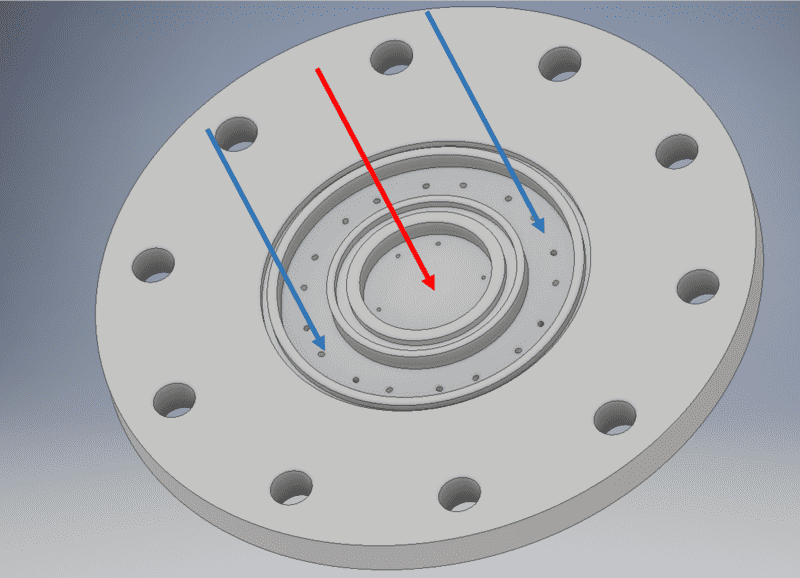

Happy 2019! I'm trying to design a mechanical face seal for the part shown below, and I'm struggling with the number of o-rings I'm supposed to use. There are two cavities (rings) for two different fluids. The liquid dynamic pressure for both the internal and external fluids is different but somewhere between 165 and 200 psi. I know I need at least two o-rings between them (as shown in the picture), but for a moment I thought maybe using three o-rings, with two of them located between both cavities would work better :/

How many o-rings would a mechanical engineer use in this case?

Roy S. Ramirez

School of Aeronautics and Astronautics

Purdue University - Class of 2021

Management and French Minor

<< Personal e-mail and phone number deleted by the Mentors >>

Happy 2019! I'm trying to design a mechanical face seal for the part shown below, and I'm struggling with the number of o-rings I'm supposed to use. There are two cavities (rings) for two different fluids. The liquid dynamic pressure for both the internal and external fluids is different but somewhere between 165 and 200 psi. I know I need at least two o-rings between them (as shown in the picture), but for a moment I thought maybe using three o-rings, with two of them located between both cavities would work better :/

How many o-rings would a mechanical engineer use in this case?

Roy S. Ramirez

School of Aeronautics and Astronautics

Purdue University - Class of 2021

Management and French Minor

<< Personal e-mail and phone number deleted by the Mentors >>

Attachments

Last edited by a moderator: