Blad9

- 14

- 0

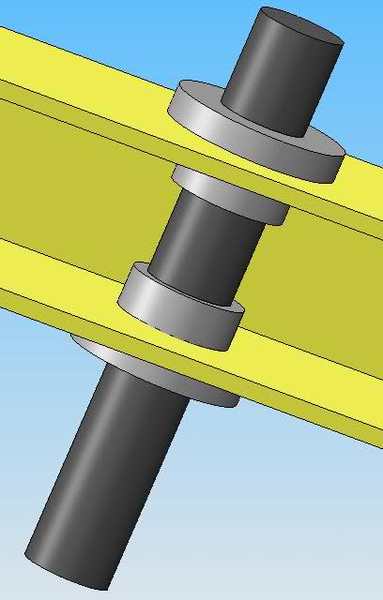

I have a shaft, which I would like to rotate 90 degrees to one side and then 90 degrees back to the other side and so forth. How should I attach the bearings to this shaft? I was thinking to do it as shown in this image:

Two slide bearings, one on the top and one on the bottom so the shaft can rotate. But how should I fix this movement vertically? I’m completely new to attaching bearings on shafts, so any help would be appreciated. It does not necessarily have to be done as shown in the image.

Two slide bearings, one on the top and one on the bottom so the shaft can rotate. But how should I fix this movement vertically? I’m completely new to attaching bearings on shafts, so any help would be appreciated. It does not necessarily have to be done as shown in the image.