zuryum

- 2

- 0

Hi,

I'm new to part design/mechanical engineering and I have the following question. I know it must be a very trivial question for most of you guys :) .. but I'm new to this.

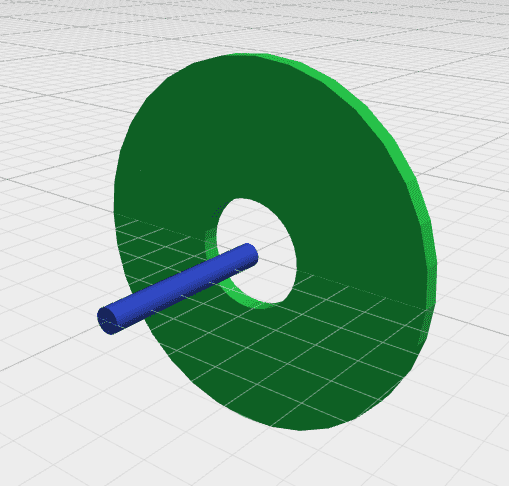

The Question: I'm wondering how can the shaft be connected to the disk?

I tried searching for bushings, various forms of couplings, etc, but couldn't find anything that can connect the two.

Does this mean I would have to machine my own coupling, and there are no standard fittings/parts that would do the job?

FYI, the project needs high torque, so I'm guessing (please correct me if I'm wrong) that a coupling needs to have a large diameter as to apply the torque at a greater distance from the center.

Thank you!

I'm new to part design/mechanical engineering and I have the following question. I know it must be a very trivial question for most of you guys :) .. but I'm new to this.

- Blue: steel shaft, 5/8" diameter, connected to a motor

- Green: aluminum disk, 10" diameter, 1/2" thick, 3" hole

- Goal: the shaft should rotate the disk

The Question: I'm wondering how can the shaft be connected to the disk?

I tried searching for bushings, various forms of couplings, etc, but couldn't find anything that can connect the two.

Does this mean I would have to machine my own coupling, and there are no standard fittings/parts that would do the job?

FYI, the project needs high torque, so I'm guessing (please correct me if I'm wrong) that a coupling needs to have a large diameter as to apply the torque at a greater distance from the center.

Thank you!