KuriousKid

- 48

- 0

I'd like to make an Induction Heater design for Cooking purpose, where heat can reach up to 400-500F or so. I read in some other forums, that it's possible. So I'm trying to get more ideas and possibly learn how this can be done safely (in case I make it / if it's really safe).

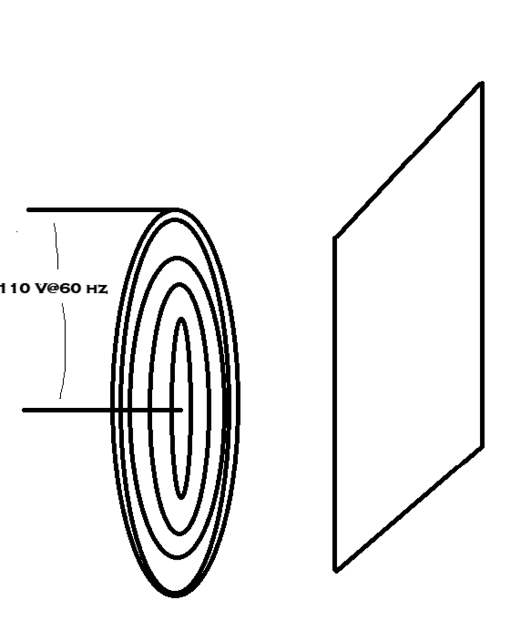

The Idea is use to 110 V 60 Hz power outlet in my Kitchen. Get a Stainless Steel Plate of 3 mm thickness. Use 12 or 13 gauge copper wire to make a pancake coil as shown in attached image with and supply it with power. To avoid Short circuit, what should I add in this circuit? I want to keep price as minimum as possible. Do I need to add a resistor in series with coil to limit current or something else?

How much efficiency difference would be there in this model and those which runs on very high frequency 20k Hz or more? Will this be slow but consume same amount of energy or anything else?

The Idea is use to 110 V 60 Hz power outlet in my Kitchen. Get a Stainless Steel Plate of 3 mm thickness. Use 12 or 13 gauge copper wire to make a pancake coil as shown in attached image with and supply it with power. To avoid Short circuit, what should I add in this circuit? I want to keep price as minimum as possible. Do I need to add a resistor in series with coil to limit current or something else?

How much efficiency difference would be there in this model and those which runs on very high frequency 20k Hz or more? Will this be slow but consume same amount of energy or anything else?