Discussion Overview

The discussion revolves around the Lewis bending equation for spur gear teeth, specifically focusing on the dependency of the Lewis form factor on the vertical distance x, which is measured from the triangle formed by the base t and fillet a. Participants explore the implications of this dependency and its representation in existing literature.

Discussion Character

- Technical explanation

- Debate/contested

Main Points Raised

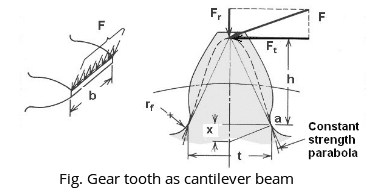

- One participant questions why the Lewis form factor depends on x and expresses curiosity about the relationship between x, height h, and width t, noting that x can be expressed as x = t²/4h.

- Another participant explains that x represents the length of the cantilever to which the tooth is simplified, referencing a source for further explanation.

- A subsequent reply reiterates that x is a separate parameter related to the tooth, distinguishing it from h and t.

- One participant expresses skepticism about the use of x in literature, suggesting that standard derivations using only the cantilever length appear more reasonable.

- Another participant agrees with the skepticism regarding the parameter x and its representation in the literature.

Areas of Agreement / Disagreement

Participants exhibit disagreement regarding the relevance and application of the parameter x in the Lewis bending equation, with some supporting its use and others questioning its validity based on existing literature.

Contextual Notes

There are unresolved questions about the definitions and assumptions related to the parameters involved in the Lewis bending equation, particularly concerning the role of x and its representation in standard derivations.