SUMMARY

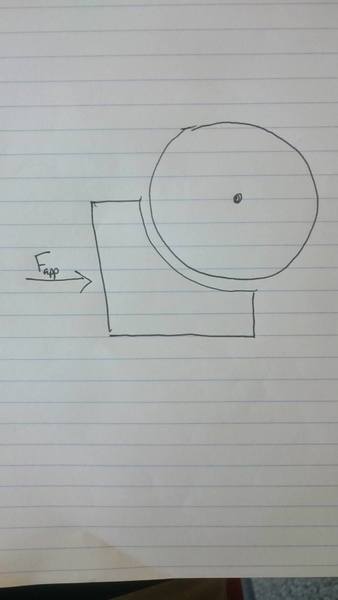

This discussion focuses on measuring friction between a metal block with a quarter circle curve and a matching metal roller. The coefficient of friction (Cfrict) can be calculated using the formula Cfrict = Ftorque / (r * Fapp), where Ftorque is the torque required to rotate the cylinder, r is the radius, and Fapp is the applied force. A practical measurement system involves using a reactive torque sensor inline between the drum and the motor, or alternatively, attaching the motor directly to the cylinder shaft to measure torque against its mountings without the need for slip rings.

PREREQUISITES

- Understanding of friction coefficients and their calculation

- Knowledge of torque measurement techniques

- Familiarity with force transducers and their applications

- Basic principles of mechanical systems and motor mounting

NEXT STEPS

- Research the use of reactive torque sensors in friction measurement

- Explore the design and implementation of force transducers in mechanical setups

- Study the principles of torque measurement in rotating systems

- Investigate cost-effective methods for measuring friction in mechanical systems

USEFUL FOR

Mechanical engineers, researchers in tribology, and anyone involved in the design and testing of frictional systems will benefit from this discussion.