- #1

Oseania

- 11

- 0

- TL;DR Summary

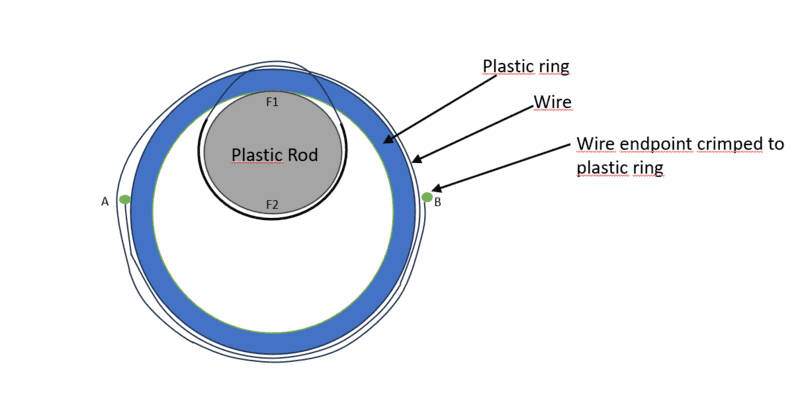

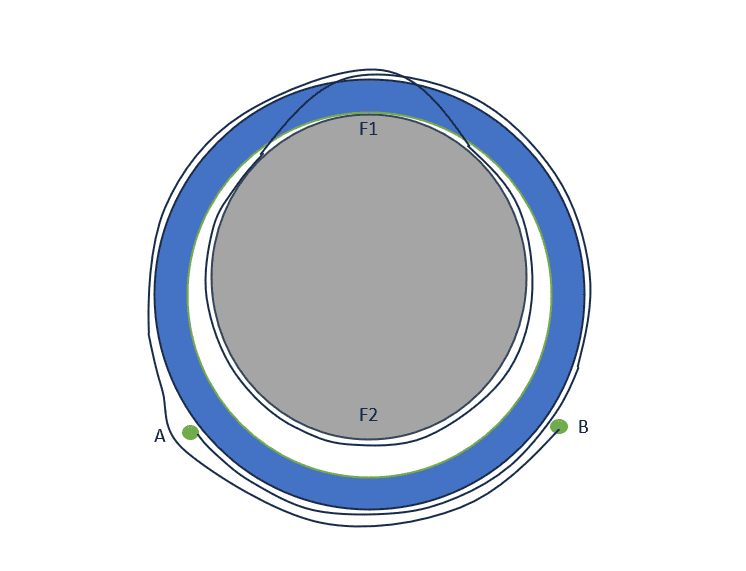

- How does capstan friction affect normal force

We have a following setup (see below). A plastic rod is placed inside a plastic ring. A wire is wrapped around a plastic rod from which it goes to the outer surface of the plastic ring. The friction coefficient between the wire and the plastic ring is about 0.1. We have several different sizes of plastic rods but the wire length always remains fixed. As such the endpoints of the wire change position according to plastic rod diameter (see second picture where points A and B have moved). In short, the smaller the diameter of plastic rod, the more we have wire in the outer ring.

We use the wire to pull the plastic rod against the inner surface of the ring. We measure the contact force F1 which is the force between the plastic rod and the inner surface of the ring. We would need to understand the relationship between F2 (the force between the wire and plastic rod) and F1 in different rod sizes.

I would assume that the friction between plastic ring and wire causes force to be lost due to capstan equation. That is, with smaller plastic rod we have more friction. As such I would assume that for given fixed force F1, the F2 varies according to the rod size? In other words we would achieve same force F1 with smaller F2 (and wire tension) with larger rods. :

We use the wire to pull the plastic rod against the inner surface of the ring. We measure the contact force F1 which is the force between the plastic rod and the inner surface of the ring. We would need to understand the relationship between F2 (the force between the wire and plastic rod) and F1 in different rod sizes.

I would assume that the friction between plastic ring and wire causes force to be lost due to capstan equation. That is, with smaller plastic rod we have more friction. As such I would assume that for given fixed force F1, the F2 varies according to the rod size? In other words we would achieve same force F1 with smaller F2 (and wire tension) with larger rods. :