- #1

bartrocs

- 27

- 0

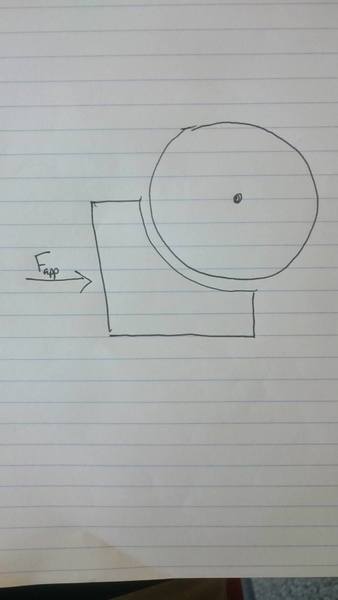

Hi, if I have a block of metal with a quarter circle curve cut out of it, and a metal roller of matching radius that contacts this curved piece, what are some ways I could go about measuring the friction between these two surfaces? The roller is fixed and the block is pushed into it with a horizontal force. See the image for clarification: