Discussion Overview

The discussion revolves around the calculation of the moment of inertia for two aluminum plates welded together. Participants explore the implications of welding versus bolting in terms of structural integrity and load-bearing capacity, considering both theoretical and practical aspects of mechanics and material strength.

Discussion Character

- Technical explanation

- Conceptual clarification

- Debate/contested

- Mathematical reasoning

Main Points Raised

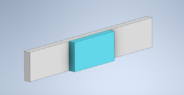

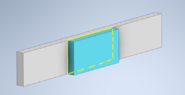

- One participant questions whether the moment of inertia can be calculated as if the welded section is a solid piece, specifically asking if the local section where the plates are connected should be considered as 2" by 1".

- Another participant expresses uncertainty about how welded plates can behave as a single load-bearing unit despite only having two continuous weld beads.

- Concerns are raised about the effectiveness of welding a smaller perimeter compared to a full perimeter, with one participant suggesting that insufficient welding would not allow the plates to be considered as one effective piece.

- Discussion includes the importance of shear flow and how welding creates a path for it, which is essential for the structural integrity of the assembly.

- Participants debate the implications of weld strength and yield stress, noting that any welding or drilling could weaken the main plates to some degree.

- References to external resources are made to support claims about built-up beams and the mechanics of materials.

Areas of Agreement / Disagreement

Participants express differing views on the effectiveness of welded connections versus bolted connections and whether the welded plates can be treated as a single unit. There is no consensus on the conditions under which the plates can be considered as one effective piece, and the discussion remains unresolved regarding the implications of different welding techniques.

Contextual Notes

Participants highlight limitations in their understanding of how welding affects the moment of inertia and structural behavior, particularly regarding the cross-sectional area that resists bending and the effects of welding on material properties.