SentinelAeon

- 31

- 3

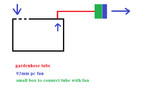

I have a plastic box and i am trying to move as much air through it as i can. I use a small garden hose to connect the box with some wall mounted fan (see the image attached). Given the small diameter of hose (2cm) and big fan (9.2cm) i am wondering if it would be better to use a smaller fan. Also, i am using axial fan intended for high flow and low static pressure (image of both fans in the attachment). Would in this case it be better to use a centrifugal fan intended for lower flow but higher static pressure ? Any data on this subject would be great, even links, so i can figure out the optimal setup given the small diameter of the hose.

edit: I found a video that explains the issue i am having and offers some results. But i am still interested in hearing your opinion.

edit: I found a video that explains the issue i am having and offers some results. But i am still interested in hearing your opinion.

Attachments

Last edited: