- #1

EfiniRX7

- 5

- 0

Ok, I have a question pertaining to the load a Macpherson strut tower sees VS. the load a particular double wishbone car sees. Basically since the macpherson strut is required to hold the weight of the car and control the cornering forces imparted through the tire/ upright, I was under the impression the strut tower is seeing a greater load force than the wishbone car.

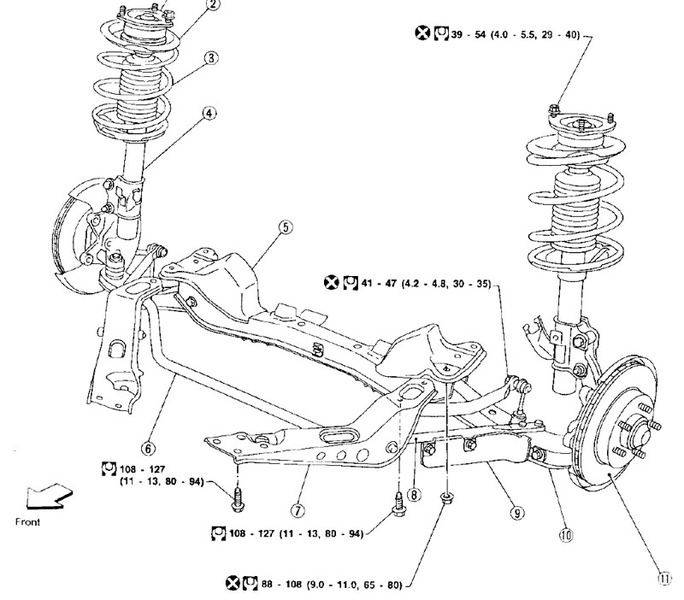

Here are pics of both systems in question

1. Macpherson strut from nissan 240sx

2. particular double wishbone from the fd3s rx7.

Im assuming that both cars weight the same, are capable of the same g-force limit, have the same wheel/ tire package, and are the same weight distribution on the chassis. Basically I want to look at this from the stand point that the front suspension is the only variable in the equation.

I was wondering if the top of the shock tower would see the same exact load on both suspension systems. I want to think that the macpherson strut will see a higher load acting on the strut tower since the cornering force, and vehicle weight is being imparted through the same load member (the strut/ spring assembly). My natural instinct is to think since the double wishbone car (fd3s rx7) only uses the shock/ spring to control the vehicle weight, and the top wishbone is controlling the lateral force through the big frame rail, the rx7 shock tower would see less load than the 240sx tower?

I know that the the force going into the chassis through the tire is identical (under my listed conditions), but I would think since the load is being dispersed over multiple points in the rx7 vs. the 240, the strut/ shock tower is being loaded less. I guess I am basically wondering if I were able to quantify the force acting on the top of the shock tower, would both shock towers have the same number even though the macpherson is a direct connection, and the rx7 is dispersing the force in multiple points?

Thanks for the help. I can provide more pictures if needed.

Here are pics of both systems in question

1. Macpherson strut from nissan 240sx

2. particular double wishbone from the fd3s rx7.

Im assuming that both cars weight the same, are capable of the same g-force limit, have the same wheel/ tire package, and are the same weight distribution on the chassis. Basically I want to look at this from the stand point that the front suspension is the only variable in the equation.

I was wondering if the top of the shock tower would see the same exact load on both suspension systems. I want to think that the macpherson strut will see a higher load acting on the strut tower since the cornering force, and vehicle weight is being imparted through the same load member (the strut/ spring assembly). My natural instinct is to think since the double wishbone car (fd3s rx7) only uses the shock/ spring to control the vehicle weight, and the top wishbone is controlling the lateral force through the big frame rail, the rx7 shock tower would see less load than the 240sx tower?

I know that the the force going into the chassis through the tire is identical (under my listed conditions), but I would think since the load is being dispersed over multiple points in the rx7 vs. the 240, the strut/ shock tower is being loaded less. I guess I am basically wondering if I were able to quantify the force acting on the top of the shock tower, would both shock towers have the same number even though the macpherson is a direct connection, and the rx7 is dispersing the force in multiple points?

Thanks for the help. I can provide more pictures if needed.

Last edited: