Discussion Overview

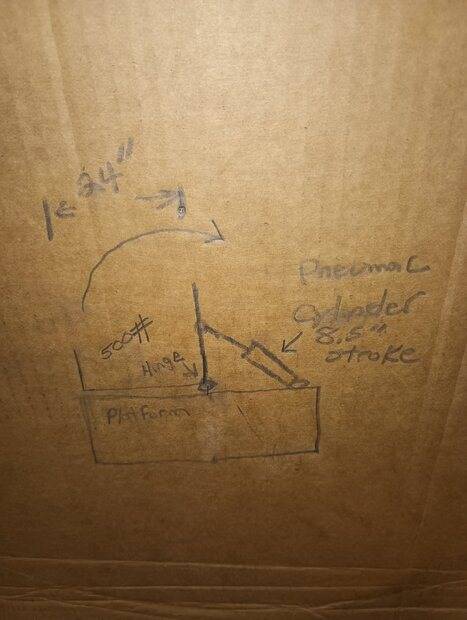

The discussion revolves around the optimal placement and stroke length of pneumatic cylinders for a device designed to tilt a 500-pound load by 20 degrees. Participants explore various configurations, geometrical considerations, and structural integrity related to the design of the platform and the pneumatic system.

Discussion Character

- Exploratory

- Technical explanation

- Debate/contested

- Mathematical reasoning

Main Points Raised

- One participant describes a device consisting of a hinged platform and inquires about the effective placement of the pneumatic cylinder.

- Another suggests mounting the cylinder at a 45-degree angle and considers using a longer stroke, though they express uncertainty about the exact length needed.

- Several participants discuss the dimensions of the cylinders, noting the importance of ensuring that the extended and retracted lengths are appropriate for the design.

- A participant mentions that the geometry of the setup requires a force greater than what the cylinder can provide at 100 PSI, suggesting that the cylinder may need to be mounted higher or more horizontally.

- There is a discussion about the structural integrity of the uprights supporting the load, with one participant expressing doubt about their strength.

- Another participant emphasizes the need to account for the rod area in force calculations when using the pneumatic cylinder, noting that it can push harder than it can pull.

- Some participants reference an online calculator for determining the necessary stroke length based on geometric considerations.

- There are multiple mentions of the air pressure available for the system, with a consensus that it is 100 PSI.

Areas of Agreement / Disagreement

Participants express various viewpoints on the optimal configuration and stroke length for the pneumatic cylinders, with no clear consensus reached. There are differing opinions on the structural adequacy of the design and the necessary calculations for force and geometry.

Contextual Notes

Participants highlight the importance of considering the geometry and structural support in the design, as well as the limitations of the pneumatic system based on the available air pressure and cylinder specifications.

Who May Find This Useful

This discussion may be of interest to individuals involved in mechanical design, engineering, or those working with pneumatic systems, particularly in applications requiring load manipulation and tilting mechanisms.