lucaszito

- 4

- 0

- TL;DR

- Human powered cardboard pulp maker

Hi everybody, first message on this forum !

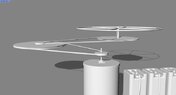

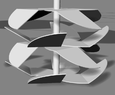

I am building a machine for a friend who works with cardboard pulp, he is also a performance artist and would like a machine where 2 or 3 performers can activate the machine by hand with pulleys and wheels, and shred the pieces of cardboard that are soaking in a container filled with water. There is 4 pulleys in total and the last driven pulley is attached to a shaft with blades on it, this whole assembly constitutes the shredding mechanism.

Currently the artist is shredding the cardboard with a hand drill on which is attached some very small DIY blades. The drill runs for about 30 minutes at 8000 RPM and he manages to get the consistency he wants.

In my idea of his machine 2 performers would spin a horizontal wheel bar of 2 meter(6.56168 feet) diameter at about 5 to 15 RPM and that wheel bar is attached to a pulley which is driving a 1:5 pulley, that 1:5 pulley is attached to a 1:1 pulley which drives another 1:5 pulley. Since the blade that will be made for this machine is about 12 times bigger than the original blade he was using, I am not sure that we need as many RPM as the drill gives. But I am not very sure either. Anyhow, I thought that just a little less RPM than the drill would do the trick, maybe 5000 if that is even doable. All pulleys will be made of wood and the wheel bar will be in steel tubes.However it is my very first time working with pulleys and ratio and I lack experience in safety, in feasibility and in physics.

I do not know how to obtain the RPM I want for the rotating blade while having a decent of size for the whole machine. Here are a few links to some pictures that give you guys dimensions and other drawings to see the machine better.

https://res.cloudinary.com/engineer...v1621112118/tips/dimensions_fltygf_rpbgnw.jpg

https://res.cloudinary.com/engineering-com/image/upload/v1620749269/tips/1_uf3o60.jpg

https://res.cloudinary.com/engineering-com/image/upload/v1620749310/tips/2_ooh7c9.jpg

Obviously the pulleys will not be floating, I just haven't thought about the structure yet, I wanted to have your opinion first.I am wondering if such a system will output the results I want, if it is durable and safe.

Thank you very much for your help !

Lucas

I am building a machine for a friend who works with cardboard pulp, he is also a performance artist and would like a machine where 2 or 3 performers can activate the machine by hand with pulleys and wheels, and shred the pieces of cardboard that are soaking in a container filled with water. There is 4 pulleys in total and the last driven pulley is attached to a shaft with blades on it, this whole assembly constitutes the shredding mechanism.

Currently the artist is shredding the cardboard with a hand drill on which is attached some very small DIY blades. The drill runs for about 30 minutes at 8000 RPM and he manages to get the consistency he wants.

In my idea of his machine 2 performers would spin a horizontal wheel bar of 2 meter(6.56168 feet) diameter at about 5 to 15 RPM and that wheel bar is attached to a pulley which is driving a 1:5 pulley, that 1:5 pulley is attached to a 1:1 pulley which drives another 1:5 pulley. Since the blade that will be made for this machine is about 12 times bigger than the original blade he was using, I am not sure that we need as many RPM as the drill gives. But I am not very sure either. Anyhow, I thought that just a little less RPM than the drill would do the trick, maybe 5000 if that is even doable. All pulleys will be made of wood and the wheel bar will be in steel tubes.However it is my very first time working with pulleys and ratio and I lack experience in safety, in feasibility and in physics.

I do not know how to obtain the RPM I want for the rotating blade while having a decent of size for the whole machine. Here are a few links to some pictures that give you guys dimensions and other drawings to see the machine better.

https://res.cloudinary.com/engineer...v1621112118/tips/dimensions_fltygf_rpbgnw.jpg

https://res.cloudinary.com/engineering-com/image/upload/v1620749269/tips/1_uf3o60.jpg

https://res.cloudinary.com/engineering-com/image/upload/v1620749310/tips/2_ooh7c9.jpg

Obviously the pulleys will not be floating, I just haven't thought about the structure yet, I wanted to have your opinion first.I am wondering if such a system will output the results I want, if it is durable and safe.

Thank you very much for your help !

Lucas