- 11,326

- 8,754

- TL;DR

- Some modern ships use a new propulsion system called Azipod. These remarkably simple and effective devices are made possible by modern power electronic cycloconverters.

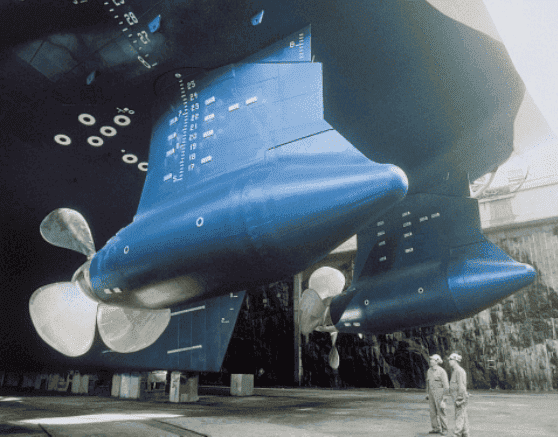

I recently came back from a cruise on MS Eurodam. The ship was equipped with two 17.6 MW Azipod propulsion systems. The captain explained a bit about them in a Q&A session, and I researched a bit more because I'm curious as an engineer. I'm sharing it here on PF for the benefit of other engineers. The innovations are more than just electrical, hence General Engineering.

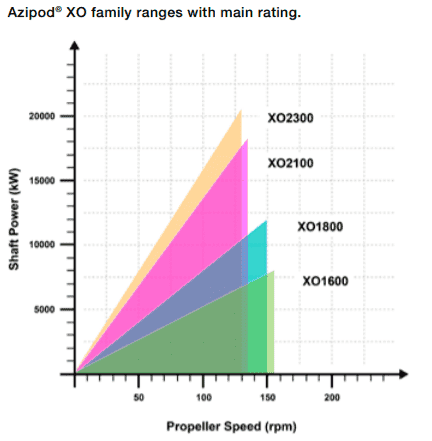

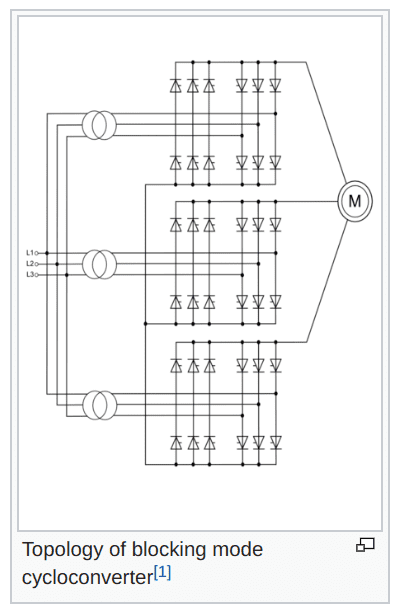

The Captain said that the ship has 6 diesel generators that produce 64 MW AC power at 11 KV (50 Hz? 60 Hz? I didn't ask.). Cycloconverters connect these fixed frequency AC sources to provide variable frequency AC power to the Azipods. Slip rings allow the Azipod to rotate for steering purposes without twisting cables.

In a recent thread, I said that the most powerful motors were synchronous AC. I was not thinking about permanent magnet synchronous. The Azipod uses permanent magnet synchronous motors, fed by a variable frequency supply, in sizes up to 20MW. Apparently, they can operate through the entire speed range from zero to maximum RPM with no special starting windings or mechanisms.

We normally think of BLDC motors as very different things than AC synchronous motors, but with a cycloconverter in the middle to convert the frequency, the difference between BLDC and AC synchronous reduces to the difference between nearly square and nearly sinusoidal waveforms. Therefore, the BLDC concept stretches from the smallest hobby drone helicopter, to motorcycles, to EVs, to the largest 20 MW marine propulsion. That's impressive.

On the mechanical side, the Azipod system eliminates long propeller shafts, through-hull penetrations with moving parts, rudders, stern thrusters, controllable-pitch propellers and reduction gears. The motor and bearings are directly cooled by sea water.

All of that leads to efficiency gains, but I don't know how much. I also imagine that 6 diesel generators plus 2 Azipods make for great reliability via simplicity and redundancy.

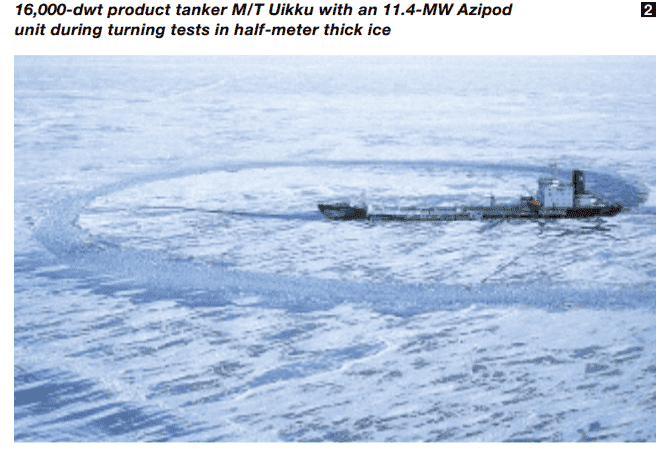

Tug boats are not needed, even in ice.

Disclosure: Azipods are a product of ABB. I am an ex-ABB employee, but in a different field. This post is not a promotion for ABB.

The Captain said that the ship has 6 diesel generators that produce 64 MW AC power at 11 KV (50 Hz? 60 Hz? I didn't ask.). Cycloconverters connect these fixed frequency AC sources to provide variable frequency AC power to the Azipods. Slip rings allow the Azipod to rotate for steering purposes without twisting cables.

In a recent thread, I said that the most powerful motors were synchronous AC. I was not thinking about permanent magnet synchronous. The Azipod uses permanent magnet synchronous motors, fed by a variable frequency supply, in sizes up to 20MW. Apparently, they can operate through the entire speed range from zero to maximum RPM with no special starting windings or mechanisms.

We normally think of BLDC motors as very different things than AC synchronous motors, but with a cycloconverter in the middle to convert the frequency, the difference between BLDC and AC synchronous reduces to the difference between nearly square and nearly sinusoidal waveforms. Therefore, the BLDC concept stretches from the smallest hobby drone helicopter, to motorcycles, to EVs, to the largest 20 MW marine propulsion. That's impressive.

On the mechanical side, the Azipod system eliminates long propeller shafts, through-hull penetrations with moving parts, rudders, stern thrusters, controllable-pitch propellers and reduction gears. The motor and bearings are directly cooled by sea water.

All of that leads to efficiency gains, but I don't know how much. I also imagine that 6 diesel generators plus 2 Azipods make for great reliability via simplicity and redundancy.

Tug boats are not needed, even in ice.

Disclosure: Azipods are a product of ABB. I am an ex-ABB employee, but in a different field. This post is not a promotion for ABB.