Vincent Mazzo

- 5

- 0

Hello guys

How can I calculate the following stiffness of the springs/suspensions in the case of inclined suspension (angle between suspension and axle)?

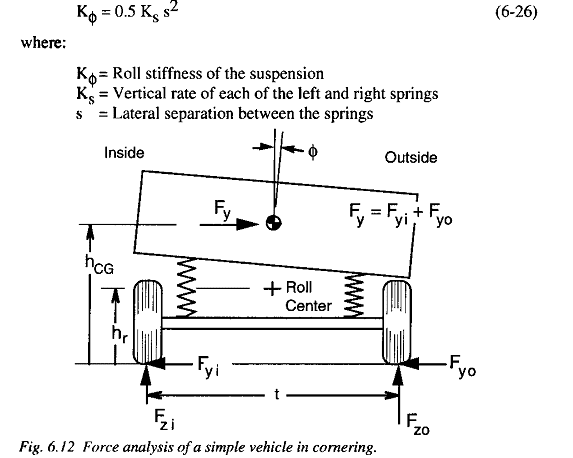

I know that the lateral separation of the springs causes them to develop a roll resisting moment proporcional to the difference roll angle between the body and the axle.

And in the case of independent suspension? How substitute the rate at the wheel for K_s and use the tread as the separation distance?

How can I calculate the following stiffness of the springs/suspensions in the case of inclined suspension (angle between suspension and axle)?

I know that the lateral separation of the springs causes them to develop a roll resisting moment proporcional to the difference roll angle between the body and the axle.

And in the case of independent suspension? How substitute the rate at the wheel for K_s and use the tread as the separation distance?