karabiner98k

- 90

- 12

Hi everyone.

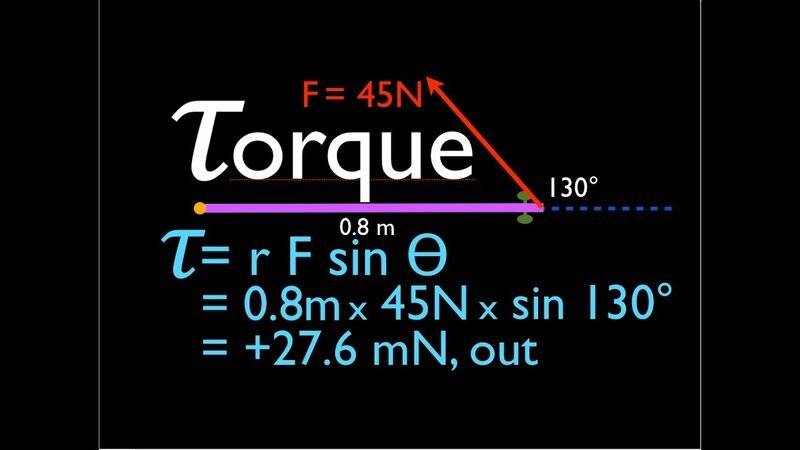

In most cases when torque and lever arm are being discussed, it is the angle between the force and the arm that matters (like in the following picture).

However, non of the articles that I have read so far have mentioned anything about the distance between force and fastener being straight or not.

However, non of the articles that I have read so far have mentioned anything about the distance between force and fastener being straight or not.

I have made an extension for my torque wrench (effective length = 0.4 meter) but due to ratchet gears of the wrench, I can't attach it to the extension in a way that both form a straight line. There is a small angle between the extension and the wrench as can be seen in the following picture specified with a blue arrow:

If the angle is between the force and the lever, we use sin(θ) to calculate torque but what about this angle? How does it affect the final torque output? What if the distance from the fastener is not straight? How do you calculate torque in this special case (Assuming (θ) = 3 degrees) ?

If the angle is between the force and the lever, we use sin(θ) to calculate torque but what about this angle? How does it affect the final torque output? What if the distance from the fastener is not straight? How do you calculate torque in this special case (Assuming (θ) = 3 degrees) ?

Force = 18 kg (176.5 N)

(θ) = 3 degrees

Total length = 0.895 meter

In most cases when torque and lever arm are being discussed, it is the angle between the force and the arm that matters (like in the following picture).

I have made an extension for my torque wrench (effective length = 0.4 meter) but due to ratchet gears of the wrench, I can't attach it to the extension in a way that both form a straight line. There is a small angle between the extension and the wrench as can be seen in the following picture specified with a blue arrow:

Force = 18 kg (176.5 N)

(θ) = 3 degrees

Total length = 0.895 meter

Last edited: