Haotranphotomask

- 20

- 7

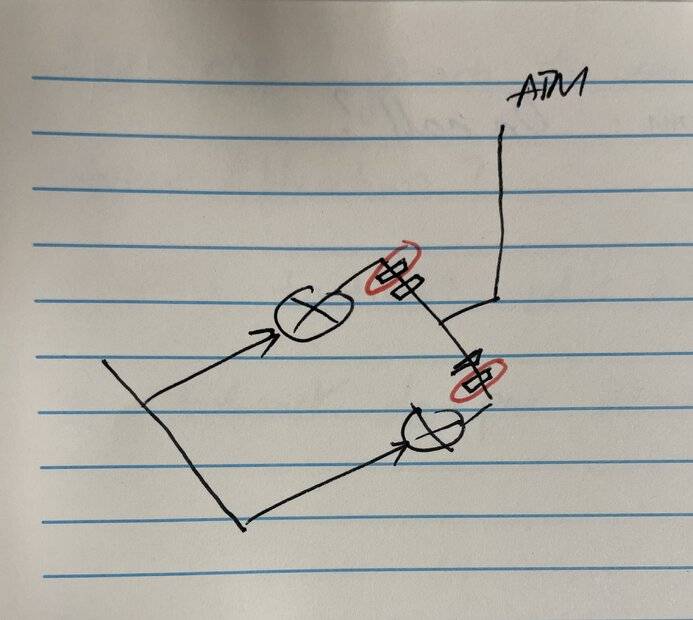

Hello, I have a system where two exhaust fans are running simultaneously. However, they both discharge to the same outlet. The suction pressure seems to be quite stable, but the discharge pressure fluctuates between 2" wc to 4" wc frequently. Below is a rough setup of my system. The rectangles are the dampers that we have on the discharge side. The ones with the red circles are dampers with a linkage and secured. The other ones are backdraft dampers and are not staying in place. I believe this happens due to both fans discharging to the same header, which causes the airflow to fluctuate the backdraft dampers.

My questions are:

My questions are:

- Does this setup cause a reduced efficiency of the fans?

- Would it be possible to lock open the backdraft dampers to reduce the static pressure fluctuations? I cannot find any codes referring to not locking the backdraft dampers. I understand the risk of fan shutting down and having air circle back into the rooms. If I accept that risk, would it be a possible solution short term?