Shelnutt2

- 57

- 0

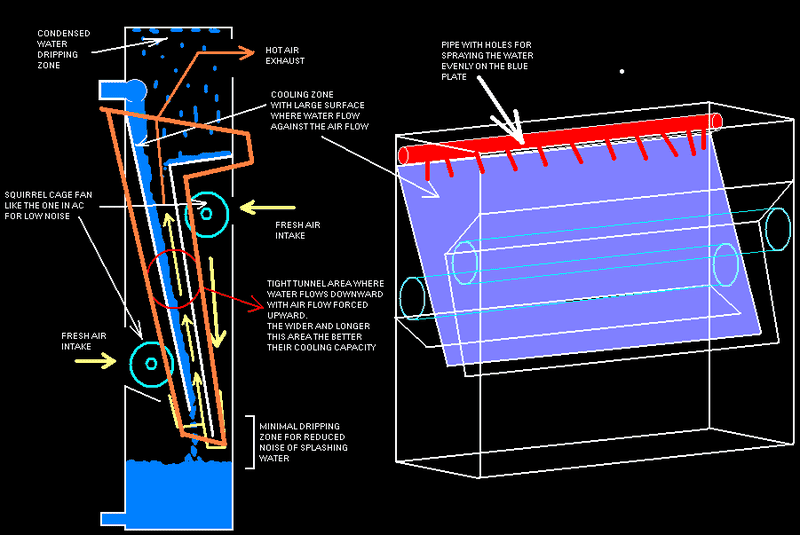

I am working on a project, all details can be found http://www.overclockers.com/forums/showthread.php?t=680115" is the catalog page with the options. I've googled about annealed and "dead soft" however I still can't tell exactly how soft/flexible it is. All I need it to support is water running. I also know the aluminum isn't the best for bending but I've read that at such thin pieces I should be able to get one bend out of it.

Also perhaps there is a better metal to use in this case? I'd like to keep it cheap, but if there is something else around the price of the aluminum then its good.

Also perhaps there is a better metal to use in this case? I'd like to keep it cheap, but if there is something else around the price of the aluminum then its good.

Last edited by a moderator: